Request a Quote

Request a Quote

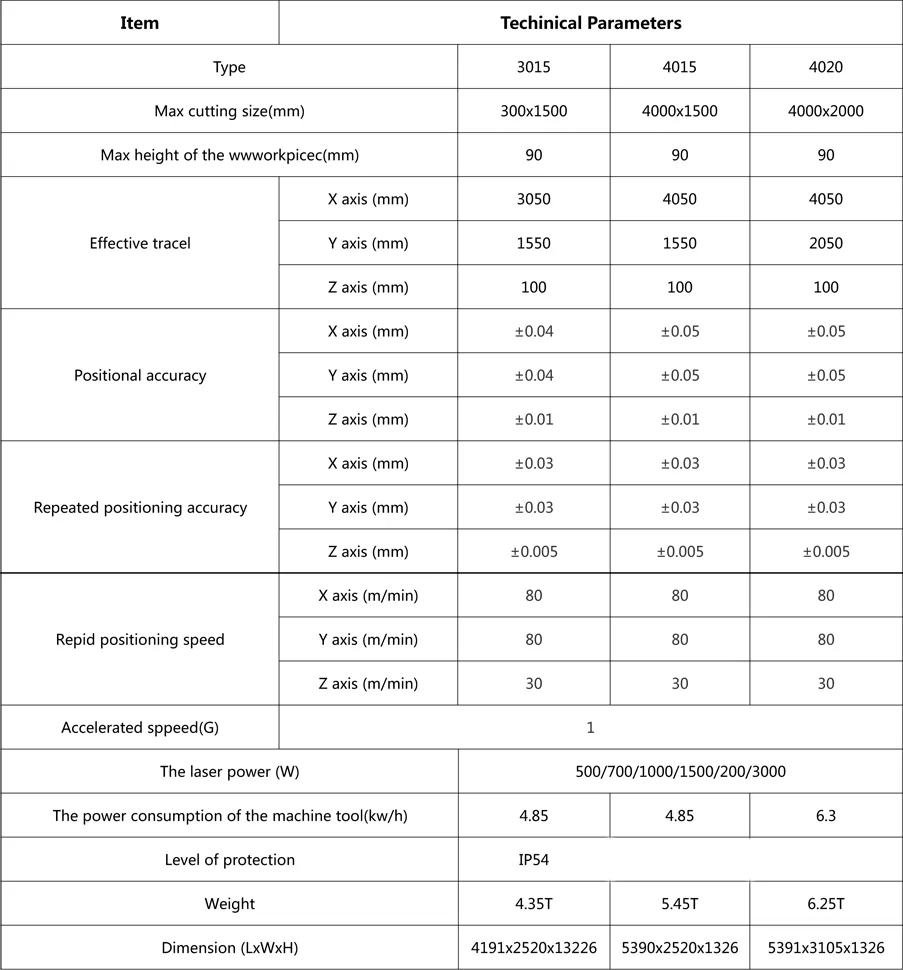

1. Focus spot is smaller, more efficient, better processing quality;

2. High electro-optical conversion efficiency: fiber laser cutting machine than CO2 laser cutting machine electro-optical conversion efficiency of 3 times, energy saving and environmental protection;

3. Very high cutting speed: 2 times the same power CO2 laser cutting machine;

4. High stability: the use of the world's top imported fiber lasers, stable performance, the key components of the service life of up to 100,000 hours;

5. Very low cost of use: machine power consumption is only 20-30% of similar CO2 laser cutting machine;

1. Carbon steel cutting:

Modern laser cutting system can cut the maximum thickness of carbon steel plate close to 20mm, the thin slit can be narrowed to about 0.1mm. Laser cutting low carbon steel its heat affected zone is very small, and cut every smooth, smooth, good vertical. For high carbon steel, laser cutting trimming quality is better than low carbon steel, but its heat affected zone is larger.

2. Aluminum and alloy sheet cutting:

Aluminum cutting is melting and cutting, to assist the gas to the cutting zone of the melt blown away, can get a better quality of the cut. At present, the maximum thickness of the cut aluminum plate is 1.5mm.

3. Alloy steel plate cutting:

Most of the alloy steel can be laser cutting, trimming quality is good. But with high tungsten tool steel and hot stencil, laser cutting will have erosion and sticky slag.

4. Stainless steel cutting:

Fiber laser cutting is easier to cut stainless steel sheet. With high power YAG laser cutting system, cutting stainless steel maximum thickness of up to 4mm.

5. Other metal cutting:

Copper is not suitable for laser cutting, cutting is very thin. Titanium and titanium alloy, nickel alloy can be used most of the laser cutting.