Request a Quote

Request a Quote

Anhui LIFU(Durmark) Machinery Technology Co., Ltd. Durmark is a professional metalworking machinery and shearing machine manufacturer from China. Our professional R&D team is very happy to share some of our experience and technology, you are welcome to communicate with us.

If you want to buy an industrial shearing machine to expand your business, then you must know more about the information knowledge of the shearing machine. Many people only know that the sheet metal shearing machine is used to cut various materials, but they don't know much about other aspects. Our introduction to the shearing machine has been updated in 2025.

In this article, expect to learn

Shearing machine definition: Shearing machine uses a moving upper blade and a fixed lower blade to apply shearing force to metal sheets of various thicknesses by using a reasonable blade gap to make the sheets break and separate according to the required size.

The shearing machine is a kind of forging machinery, and its main function is the metal processing industry. The products are widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automobile, electric power, electrical appliances, decoration and other industries to provide special machinery and complete sets of equipment required.

Shearing machine is a machine that uses one blade to reciprocate linear motion relative to the other blade to cut the plate.

The shearing machine after shearing should be able to ensure the straightness and parallelism of the shearing surface of the sheared sheet, minimize the deformation of the sheet, and obtain high-quality workpieces.

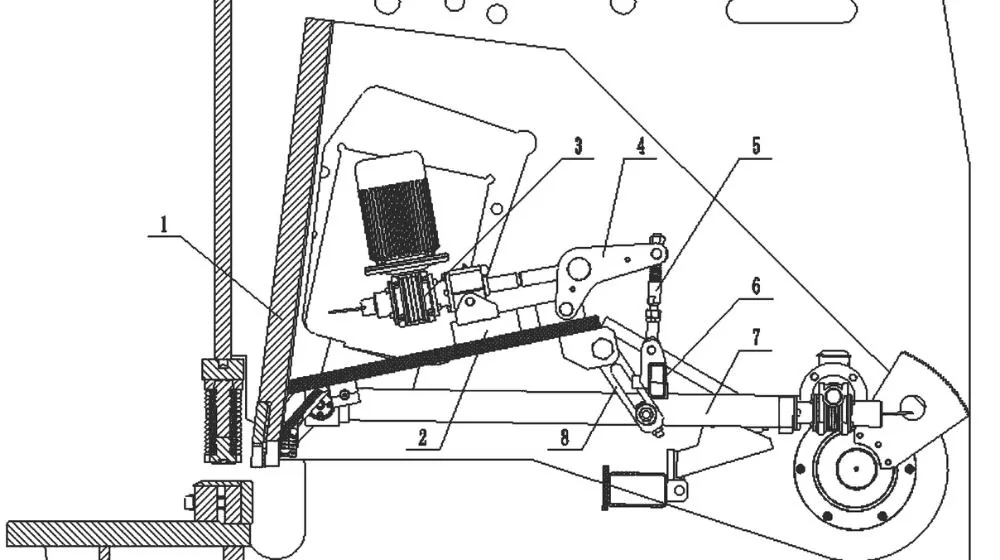

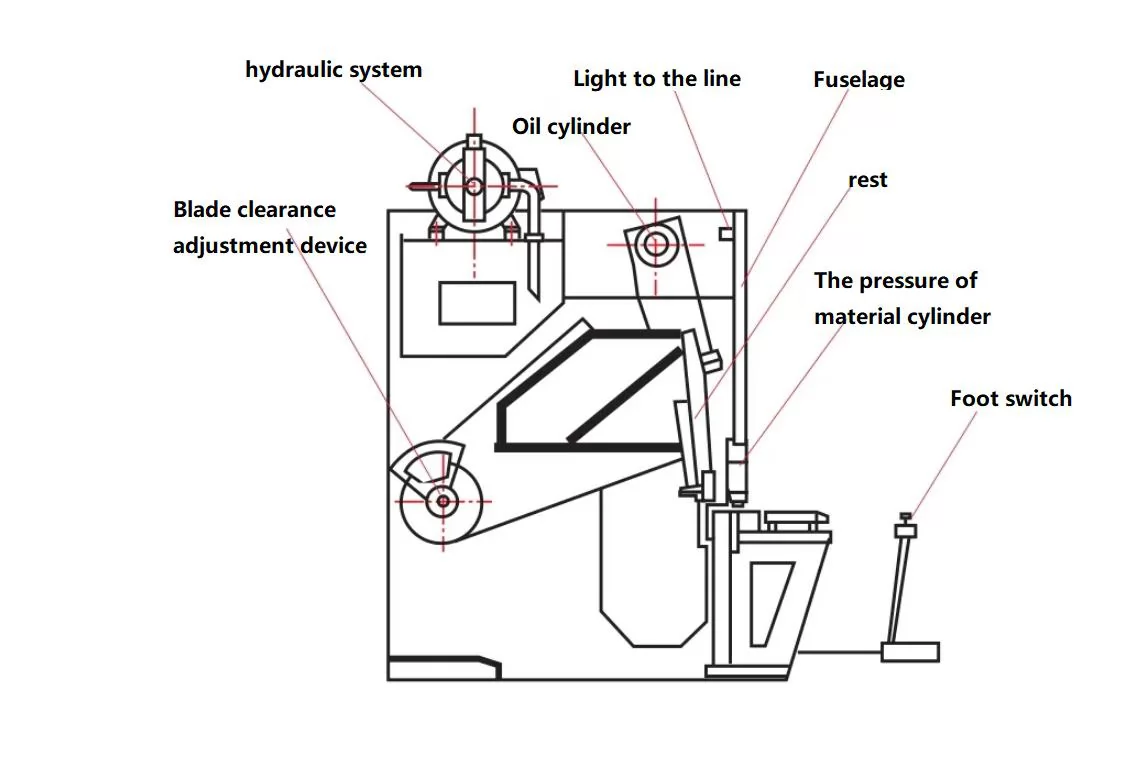

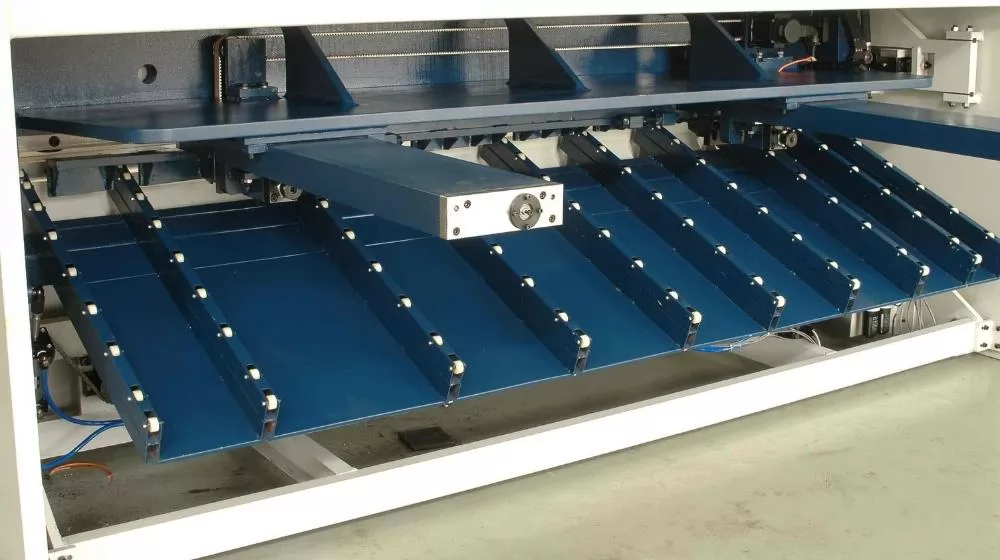

The upper blade of the shearing machine is fixed on the knife holder, and the lower blade is fixed on the worktable. The worktable is equipped with a holding ball to prevent the board from being scratched when sliding on it.

The back gauge is used to position the plate, and the position is adjusted by the motor.

The pressing cylinder is used to hold down the sheet to prevent the sheet from moving during the shearing process.

Guardrails are safety devices to prevent industrial accidents. The return journey generally relies on nitrogen, which is fast and has little impact.

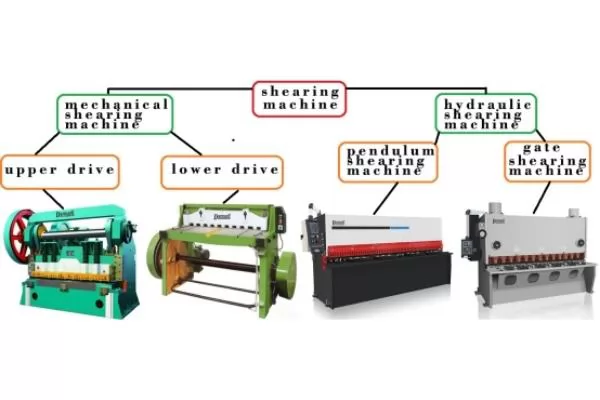

Types of shear machines: General shears can be divided into pedal type (manpower), mechanical shears, electric shears, hydrualic swing shears, and guillotine shears.

Mechanical shearing machine is divided into: upper drive and lower drive

Hydrualic shearing machine is divided into: pendulum shearing machine and gate shearing machine

Linear shears are used to cut metal thicker than 2mm, they are operated by hydrualic power or manual machines to cut thinner metal.

Circular shears are used to cut circular blanks and rings from metal and are driven by electric motors. The best metal types for shearing are bronze, aluminum, brass and mild steel. Metal shearing is cost-effective and easy, so it is preferred in industry and even in the home.

1.Bench Shearing Machine

The machine is mounted on a tabletop to increase its mechanical capabilities. It is used to cut rough shapes of medium-sized metal. However, small bench shears come with ground cutting blades that are lightweight for clean and quick cuts.

2.Guillotine

Mechanically driven guillotine shears workflow: The material to be cut is first squeezed with a plunger, the moving blade descends and shears the metal. Electric shears consist of a shearing table to place the material to be sheared, a holding device to keep the material in place to avoid movement, a measuring device to ensure the material is in the correct position, and upper and lower blades for cutting .

3.Power shears

These types of shears are powered to shear large pieces of metal, no matter the size. Alternatively, they can be hydrualically driven to cut metal that is too bulky to transport.

4.Throat

This means that the metal being cut can move freely around the cutting blade, so it is flexible. It is used for complex cuts and curves.

For more types of shears, please click here.

Shearing machines are commonly used for cutting metal sheets, steel plates, aluminum sheets, etc., for the production of automotive components, machinery parts, steel structures, etc.

Used for cutting and processing construction materials such as reinforcing bars, steel plates, etc., for the fabrication of building structures and components.

Shearing machines are used for cutting automotive body panels and parts such as doors, roofs, as well as manufacturing chassis components.

Used for machining metal components of aircraft, spacecraft, as well as outer casings and structural components of aerospace vehicles.

Used for cutting and processing metal enclosures, metal sheets, etc., for electronic products such as phones, computers, etc.

Shearing machines can be used for processing metal components of furniture such as tables, chairs, cabinets, etc.

Shearing machines are used in the cutting and shaping of metal sheets and steel during steelmaking and processing.

Shearing machines are used for processing metal components of agricultural machinery such as harvesters, tractors, etc.

A shearing machine typically consists of the following parts and units:

This provides a stable foundation for the machine. The entire body of the machine is strong, durable and reliable.

This is attached to the bed and remains stationary during the cutting process. It serves as the stationary cutting edge.

This is mounted on a sliding mechanism and moves back and forth across the fixed blade to perform the cutting action. It serves as the movable cutting edge.

This clamps the workpiece in place during the cutting process. It helps to keep the workpiece stable and prevent it from moving during the cutting process.

This helps to align the workpiece and keep it in position during the cutting process. It helps to ensure that the workpiece is cut at the correct angle and location.

This controls the movement of the moving blade. It can be a foot pedal or hand lever that the operator uses to start and stop the cutting process.

This allows the operator to adjust the angle of the blades relative to each other. It allows the operator to adjust the angle of the blades to suit the specific cutting requirements of the workpiece.

These are designed to protect the operator from the cutting action. They are usually placed around the blades and other moving parts of the machine to prevent accidents.

These are the main parts of the shearing machine, their functions are as described above, depending on the specific design of the machine, additional parts may be present.

The following situations may occur during the use of the plate shearing machine:

Start the shearing machine for idling several cycles, to ensure that under normal conditions, try to shear different thickness of the sheet, from thin to thick. Ensure users are familiar with the shearing machine performance.

The test shear plate thickness must be adjusted to different blade clearance. If the blade clearance is not adjusted, the durability of the blade will be affected.

Open the pressure gauge switch and observe the oil pressure value during the shearing process. The pressure should be less than 20MPa when cutting 12mm plate. The pressure of the remote pressure regulating valve No9 is set at 20-22mpa when it leaves the factory. The user must abide by this regulation and shall not increase the pressure for cutting beyond the specified material surface, resulting in machine damage.

Sound balance during operation. Stop the shearing machine for inspection if there is any noise.

When the plate shearer operates, the temperature of the fuel tank increases. 60 degrees, over which the power off rest.

CNC shears before feeding using a mobile rear stopper device and electronic counter, easy to adjust the position of rear stopper.

The whole welding frame structure is used, and the vibration aging treatment, the machine has good rigidity, high precision and good precision retention.

The tool rest adopts steel structure. Under the action of oil cylinder, it moves up and down along the roller to realize shearing action.

The front feeding frame adopts steel structure, which is tempered to eliminate internal stress, strong rigidity and good stability.

The forward feed adopts imported precision ball screw, linear guide guide, and digital AC servo motor drive.

The positioning is accurate, the operation is fast and stable, and the front feeding table is arranged with steel balls and brushes.

The positioning speed of the three-axis CNC motor can be adjusted arbitrarily to improve work efficiency.

The parameter adjustment function is set in the system, and the reference points of the two axes can be modified arbitrarily. Thereby adjusting the positioning value of the numerical control system.

The system is equipped with an automatic knife retract function, which can make the feeder retreat in time during the cutting process to avoid friction between the blade and the plate during the cutting process.

After each startup or shutdown, the two axes controlled by the CNC system can automatically find the reference point when the machine is restarted to ensure repeatable positioning accuracy.

If you are familiar with the metal fabrication process, you may be wondering what is the difference between shearing and die cutting. In fact, they are both cutting or finishing processes that involve using a blade to remove excess material or create the desired shape for sheet metal. The main difference is that shearing uses straight edged blades, whereas the blades used in die cutting are curved.

As we mentioned in the opening paragraph, shearing has become a popular and accepted practice in metal fabrication. In fact, this method has many distinct advantages.

First, the metal can be sheared without heating. This process is usually carried out at room temperature or when the metal is cold.

Second, it produces far less waste than other manufacturing practices. This allows manufacturers to save on cleaning costs and perform the process faster.

Finally, shearing can be used on a variety of metals, including stainless steel, bronze, aluminum, copper, and iron, to name a few.

While shearing has many significant advantages, there are also some potential disadvantages to be aware of.

First, exceptionally hard metals like tungsten cannot be sheared.

Second, shearing can cause the stainless steel plate to deform if not handled carefully.

Ways to find a shearing machine manufacturer in China include

Online platforms such as Alibaba and Made in China are ideal places for different shearing machine manufacturers to market to their customers.

Manufacturers can often offer you different prices and after-sales services.

When searching on these sites, you have to make sure that you are choosing a manufacturer and not a distributor or trader.

Also, do not start a transaction with a specific manufacturer until you have verified their credentials.

The advantage of having a large number of manufacturers on these sites is that you can negotiate or select the right manufacturer for your automatic power press.

You also have the opportunity to negotiate the price of your product.

Most good manufacturers of shearing machine have their own websites to advertise their products.

However, many good Chinese manufacturers do not pay much attention to this or start late, but this does not mean that they cannot offer excellent products.

So it may be hard to find them in the first few pages, but you can check out a few pages with many good shearing machine manufacturers to choose from.

Or you can add "China" to the keywords to see more Chinese manufacturers.

Many sourcing agents in China are aware of the different shearing machine manufacturers in China.

They know the production capabilities and pricing of these manufacturers.

These are important specifications that your sourcing agent can help you with when searching for a m

Sourcing agents can also save you the hassle of finding a reliable manufacturer as they usually have a ready-made list for you to choose from.

The main limitation of using a sourcing agent is the high cost of finding a manufacturer.

If you place a bet on finding a manufacturer, it is impossible to compare what you pay here with what you might lose.

Whenever a China trade show is held in your country or in China, you should expect Chinese manufacturers to showcase their products.

This allows you to interact with different manufacturers and ask them about different aspects of their manufacturing process.

The advantage of this approach is that you can meet face-to-face with a specific manufacturer.

This allows you to negotiate with the manufacturer on different specifications.

Common trade shows and fairs in China include: Canton Fair, etc.

It is vital that once you have reached an agreement with a particular manufacturer, you need to visit their premises before you start production.

Determine the purpose of the machine and select a model that is designed for your specific needs. Make sure the machine has the right capacity to handle your workpiece sizes and thicknesses.

First of all, it is necessary to clarify which type of shears they are suitable for. There are not only several types of shears, but also different specifications. Therefore, when choosing, you should pay attention to this aspect, especially if the shears are capable of cutting different The thickness of the material can be known, so after these aspects are determined, the next step is selected.

Before choosing a shearing machine, customers must check the power supply and various components of the shearing machine. When purchasing a shearing machine, users must know what specifications of the shearing machine they need, and go to a few more to see the price and performance of the shearing machine. After selecting the model you need.

The user can ask the manufacturer to try the shearing machine. During use, the user must carefully observe the sharpness of the blade of the shearing machine and whether the shearing machine is noisy. If the body of the shearing machine is noisy, the manufacturer must request the shearing machine to be replaced. Because the shearing machine is a large-scale machine, once it appears in the process of use, it is not a small project for enterprises or after-sales maintenance.

Look for a machine with good accuracy and repeatability. This will ensure that you get consistent cuts and minimize waste.

Choose a machine that has built-in safety features, such as guards and emergency stop buttons, to protect your operators.

Look for a machine that is user-friendly and easy to operate. This will reduce the time it takes to set up and change over to different jobs.

Choose a machine that is easy to maintain and has a low cost of ownership. Check for parts availability and the manufacturer's warranty.

Consider the reputation of the manufacturer. A well-respected brand is more likely to produce high-quality machines and provide good customer support.

Set a budget and choose a machine that offers the best value for your money, taking into account the other factors mentioned above.

Hydrualic shears are fast and accurate and can easily cut large quantities of metal in the factory.

Hydrualic shears do not require as much maintenance as mechanical models and are therefore cost-effective.

Hydrualic shears are generally compact machines, so even though they apply the same pressure as mechanical shears, they take up less space.

Hydrualic shears hold metal with cramps while cutting, ensuring smooth cuts even 90-degree cuts. There are a wide variety of hydrualic shears on the market to suit all sizes of metal.

Always have professional operators working on the machine

Keep the machine clean and follow the operating rules to avoid danger.

Be sure to turn off the power of the machine after use.

During the purchase, the following points should be noted:

Determine the specifications and parameters of the purchased machine according to your own needs and parameters, and at the same time consider the needs of future expansion of the enterprise, leaving a certain margin to determine the parameters of the machine. Especially for the shearing machine, for the material thickness of the material to be sheared, the size of the slitting machine and other requirements, after the machine model parameters are determined, you can contact the manufacturer to purchase.

Identify which manufacturers make the machine you want to buy.

In this link, it is often the easiest to ignore, because no matter which manufacturer is contacted, the manufacturer will basically inform the professional production of this type of product.

In fact, the models produced by different manufacturers are often different, and manufacturers often provide various products by adjusting goods.

Therefore, users should pay special attention to choosing the one that suits them best.

You can read this article to learn about the top 10 global shearing machine manufacturers, including China Hydrualic shearing machine companies.

After contacting several companies that produce machines and obtaining the price, parameters, payment method and shipping method of the machine, the most important step is to choose the manufacturer to buy. Generally, after removing the highest price and the lowest price, choose a reliable manufacturer, so as to obtain a better price/performance ratio while ensuring the quality and after-sales service.

Select several special manufacturers as a comparison to understand the use, quality of the machine, especially after-sales service. Taking all into consideration, choose the manufacturer with the best price and the best service.

After confirming the manufacturer, the next step is to sign a contract, pay a deposit, take delivery or cash on delivery and other related matters. When signing a contract with a manufacturer, be sure to check whether the contract terms are breached or unreasonable.

Obtain key documents, including quality inspection reports, product test reports, etc.

More information can be read: Top 10 Shearing Machine Manufacturers

JMT offers a selection of high-quality, high-production metal shearing machines for sale that are a cut above the competition. With our superior designed hydrualic shearing machine lineup, all possible sheet metal and plate cutting jobs and requirements will be met, by one or the other of our three series of shearing machines. Whether it be a need for a hydrualic shear consider our Variable Rake Guillotine Shear or our Swing Beam Shear, or maybe you're considering a Power Operated Mechanical Shear, either way, no base is left uncovered.

JEAN PERROT is a designer and manufacturer of guillotine shearing machine and hydrualic shearing machine. These high-performance shearing solutions feature a wide range of shears and are ideal for high-speed, high-efficiency shearing.

JEAN PERROT has a range of shears including entry, intermediate and advanced. JEAN PERROT is an excellent choice for those looking for a catalog of machines with a wide price range. Entry-level shears are known for their cost-effective prices while maintaining high quality and high performance, making them a great option for those looking for an economical solution.

Durmark is a professional shearing machine manufacturer in China, specializing in providing customized shearing machine services for global customers. The machines we produce are low in price, stable in performance, and complete in functions. They are very suitable for industrial metal cutting.

All of our shears have passed ISO 9001:2008 certification and comply with international quality standards. You can buy with confidence. Whether you need Sheet Metal Shearing Machine, Guillotine Shearing Machine, or Swing Beam Shearing Machine, we can provide it for you.

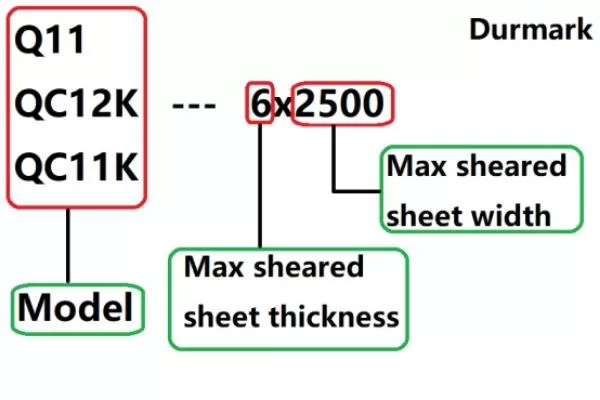

Cutting thickness: 1-25mm, (other thicknesses can be customized) Cutting length: 500-10000mm (other lengths can be customized) Metal materials that can be cut: carbon steel, stainless steel, aluminum plate, galvanized plate, aluminum plate, etc. (customizable)

RAJESH is one of the leading shearing machine manufacturers based in India. With a roster of hydrualic shears, RAJESH ensures safety and technology that is always up to date with their products. Standard equipment comes with German hydraulics and motors. Machinery is equipped with top blades controlled through servo control technology that assures efficiency and accuracy every time.

With such a huge catalog of products on the market, it can be challenging to find the right manufacturers to trust for your business and product needs. However, when it comes to finding the best shearing machinery, these nine manufacturers are reliable and reputable for their high-quality products that prioritize efficiency and longevity.

LVD is a Belgian shearing machine manufacturer, offering a full line of shearing equipment that is diverse and globally accessible. With several models in their roster, their machines are highly flexible and will meet any demanding standards your business might have.

LVD offers conventional CNC-controlled guillotine shears as well as custom shearing systems tailored to meet all of your business needs.

We are the manufacturer and supplier of shearing machine. If you need to buy or customize a shearing machine in the near future, then we can serve you. With more than 20 years of manufacturing experience, we can provide you with the best machine solutions and services. Look forward to working with you!

Quick Links:

Top 10 Shearing Machine Manufacturer

How to Choose a Right Shearing Machine Manufacturer

China Top 10 Hydraulic Press Manufacturers 2025

Top 10 Press Brake Machine Manufacturers in 2025

When it comes to shearing machines, understanding the differences between mechanical and hydraulic models is crucial for making an informed choice. Mechanical shearing machines, known for their precision and speed, are typically used for lighter, thinner materials. They operate using a flywheel and clutch mechanism, which allows for a faster production rate. On the other hand, hydraulic shearing machines use hydraulic fluid to generate force. This type of machine is ideal for cutting thicker and harder materials, offering more power and the ability to handle higher loads with ease. The choice between mechanical and hydraulic largely depends on the specific needs of the task at hand, considering factors such as material thickness, required precision, and production speed.

The size of a shearing machine significantly impacts its performance. Larger machines are capable of handling bigger and thicker materials, offering higher cutting capacity. They are generally more powerful and can accommodate larger sheets or plates. However, larger machines require more space and might have higher operational costs. Smaller shearing machines, while less powerful, are more suitable for smaller workshops or tasks that require finer precision. They are easier to operate and maintain, making them a good choice for smaller-scale operations. The key is to match the size of the machine with the specific requirements of your project, considering aspects like material size, volume of work, and available workspace.

Safety is paramount when operating shearing machines. Operators should always wear appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection. It’s essential to ensure that safety guards are in place and functioning correctly to prevent accidental contact with the blade. Regular maintenance and inspection of the machine can prevent mechanical failures and accidents. Training for operators is also crucial, as it ensures they are aware of the correct procedures and potential hazards. Additionally, keeping the work area clean and free from obstructions reduces the risk of accidents. Implementing these safety measures can significantly reduce the likelihood of injuries and ensure a safe working environment.

Absolutely! Customization of shearing machines to meet specific industrial needs is a common practice. Manufacturers often offer options to modify various aspects of these machines, such as the size, blade type, and control systems, to cater to the unique requirements of different industries. For instance, a metal fabrication industry might need a heavy-duty shearing machine with specific blade configurations, while a smaller workshop may require a compact, less powerful model. Customization allows for enhanced efficiency and precision, ensuring that the machine aligns perfectly with the operational needs of the business. By working closely with manufacturers, businesses can get a shearing machine that not only meets their current needs but also adapts to future challenges.

Technological advancements have a significant impact on the shearing machine market. Innovations in automation, control systems, and materials have led to the development of more efficient, precise, and safer machines. For example, the integration of computerized control systems allows for more precise cuts, reduces waste, and improves the overall efficiency of the cutting process. Advances in materials science have led to the development of stronger, more durable blades, which can handle tougher materials and offer longer service life. The rise of IoT (Internet of Things) and AI (Artificial Intelligence) in manufacturing also opens up possibilities for smart shearing machines that can diagnose problems, predict maintenance needs, and optimize cutting processes. These technological advancements not only enhance the capabilities of shearing machines but also drive competitiveness in the market.

.png)