Request a Quote

Request a Quote

_1650951600_WNo_1000d560.webp)

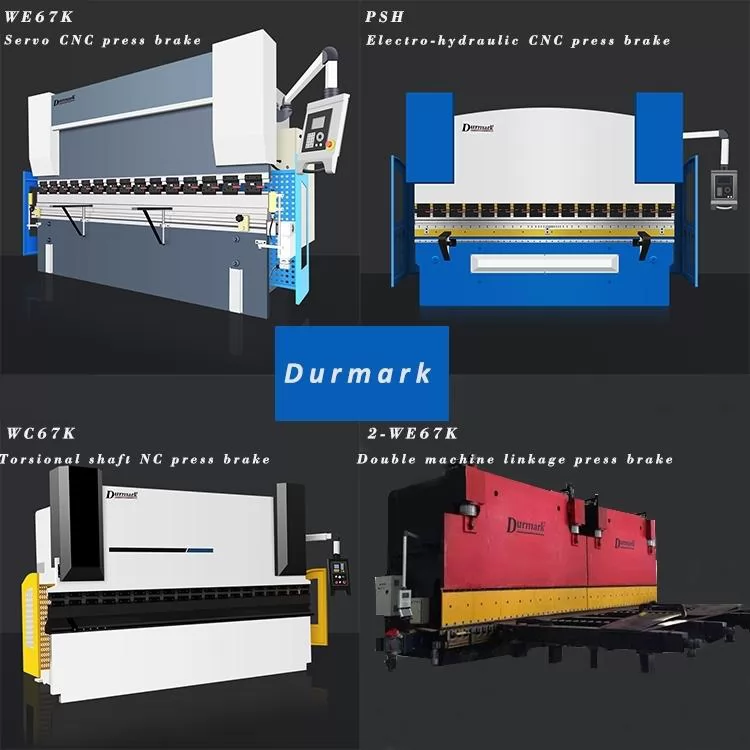

Bending machine, also known as press brake. It is a very important and commonly used machine in today's industrial production. So what is a bending machine? What are his characteristics? What kinds are there? Before buying a bending machine, we must first learn how to choose a cost-effective press brake. Today, Durmark takes you into the sea of knowledge of press brake

What is bending machine

Bending machine main classification

Structure description of bending machine

Bending machine features

Using method of bending machine

bending machine is a kind of can be carried out on the thin plate bending machine, the structure mainly includes the bracket, workbench and clamping plate, workbench on the scaffold, workbench consists of base and the clamp, the base through the hinge is connected with the clamping plate, the base is composed of shell, the coil and plate, coil placed inside the shell of the sag, the depression at the top of the cover plate. When used, the wire is energized to the coil, and after energized, the pressure plate produces gravity, so as to achieve the clamping between the pressure plate and the base plate. Due to the use of electromagnetic force clamping, the pressure plate can be made into a variety of work-piece requirements, and the work-piece can be processed on the side wall, the operation is also very simple.

Hydraulic bending machine comprises a bracket, a table and a clamping plate, the table is arranged on the bracket, the table is composed of a base and a clamping plate, the base is connected with the clamping plate through a hinge, the base is composed of a shell, a coil and a cover plate, the coil is placed in the depression of the shell, the top of the depression is covered with a cover plate.

When used, the wire is energized to the coil, and after energized, the pressure plate produces gravity, so as to achieve the clamping between the pressure plate and the base plate. Due to the use of electromagnetic force clamping, the pressure plate can be made into a variety of work piece requirements, and the work piece can be processed on the side wall. press brake can be replaced by press brake die, so as to meet the needs of various work piece.

Servo torsional shaft bending machine

Double machine linkage bending machine

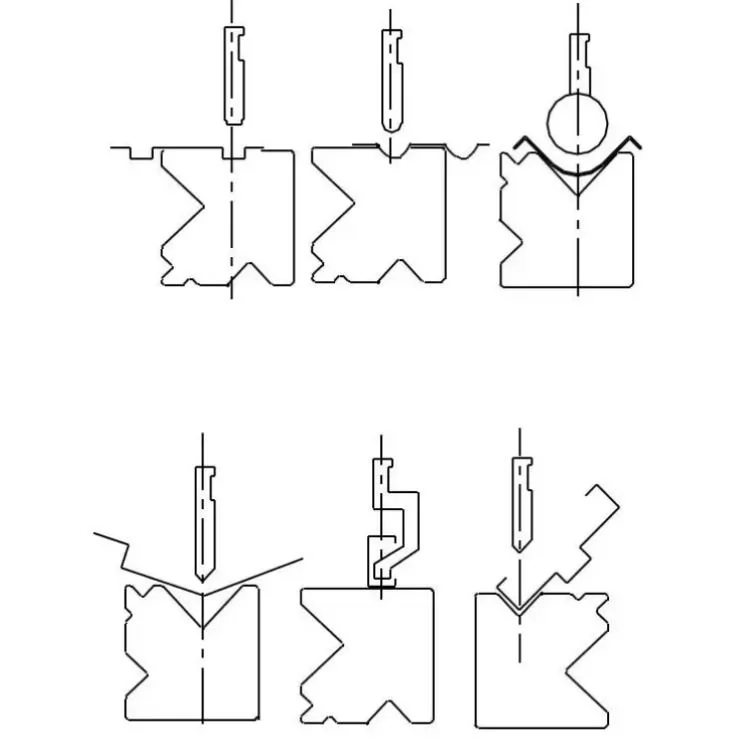

Bending machine is an important equipment of sheet metal industry work-piece bending forming, its role is to press the steel plate according to the process needs into various shapes of parts. Such as the hydraulic sheet metal press brake structure diagram shown below, is mainly composed of left and right column, workbench, beam frame, oil cylinder fixed on the upright post, around the slider and the oil cylinder piston connection, movement up and down the fixed to the column on the guide rail, lower die is fixed on the workbench, the lower upper die is installed on the slider, hydraulic system, electrical system instructions are given, under the influence of oil cylinder, The slide block drives the upper die down and the lower die to realize the bending of the sheet metal. The left and right columns, worktable and slider (hereinafter referred to as the three parts) are the key parts of the bending machine, the weight of the three parts of the total weight of a press brake70%~80%. Its strength and rigidity directly determine the operation precision of the machine tool, service life, and the accuracy of the work-piece.

Slide block part: hydraulic transmission, the slide block part is composed of slide block, oil cylinder and mechanical block fine tuning structure. The left and right cylinders are fixed on the frame, and the piston (rod) drives the slider up and down through hydraulic pressure, and the mechanical block is controlled and adjusted by the numerical control system.

The work table part: operated by the button box, so that the motor drives the stopper frame to move before and after, and controlled by the numerical control system to move the distance, its minimum reading is 0.01 mm (before and after the position are travel switch limit);

Synchronization system: the machine is composed of torsion shaft, swing arm, joint bearing and other mechanical synchronization mechanism, simple structure, stable and reliable performance, high synchronization accuracy. The mechanical block is adjusted by the motor, and the numerical control system controls the value;

Stopper mechanism: stopper adopts motor drive, drives two screw synchronous movement through chain operation, numerical control system controls the size of stopper.

Hydraulic bending machine processing Q235 sheet to do a simple introduction.

Switch on the power supply, release the emergency stop button, open the key switch on the control panel, and then press the oil pump to start.

Cylinder stroke adjustment, the use of press brake must pay attention to the adjustment of cylinder stroke, must be tested before bending. bending machine die down to the bottom must ensure that there is a plate thickness clearance. Otherwise, the mold and the machine will be damaged. Stroke adjustment is also electric quick adjustment and manual fine tuning.

Bending notch selection, generally choose the plate thickness of 8 times the width of the notch. For bending 4mm sheet metal, choose a notch of about 32mm.

Rear stopper adjustment generally has electric quick adjustment and manual fine tuning.

Step on the foot switch to start bending, press brake and shearing machine is different, can be loosened at any time, loosen the foot bending machine will stop, and then continue to step down.

The above is the bending machine information brought to you by Durmark, I hope it can be helpful to you. If you are looking for the right press brake, then you can check out Durmark's range of press brakes. Durmark is a leading bending machine manufacturer in China, our products sell well overseas, welcome to contact us.

Read more:

List of Best Press Brakes in China

.png)