Request a Quote

Request a Quote

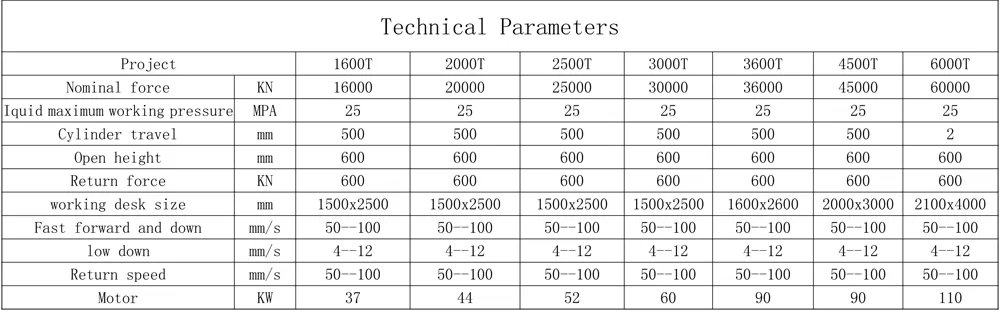

Feature:

1.This machine is characterized as high efficient, convenient and safe operating, energy saving, appearance attracting, and low cost.

2.The machine is invented and continuously improved through many of our experienced engineers, making the machine of both simply structured and well performed. It takes just a few minutes for a person to learn to operate.

Program

1.Working pressure, speed, and stroke can be set in a certain range according to different technological requirements .

2.Independent power mechanism and electrical system are controlled by press-button enabling realize manual, semi-automatic, and automatic operation.

Main Structure

Eliminate internal stress

Fuselage is made of 45# steel and treated with internal stress elimination after being weld.

Cylinder are made of 45# forging.

Piston rod are made of 50# steel (nitrided)

Rigidity up to HRC45-50

Cylinder technology:

Cylinder bottom, steel cylinder, piston, piston rod are integral forged. Material: 45# steel.

Rod guide and supporting guide ring are made of phosphor-copper instead of nylon, the stability and wear-resistant are greatly improved.

The piston rod are made through nitridation treatment and surface carburizing and quenching (depth: 0.03mm~0.04mm), and electroplating hard chromium (thickness: 0.04mm~0.05mm)

Dynamical system

The advanced two-way cartridge valve integration system is adopted.

The machine is compact structured with advantages of low noise, and stable performance. The oil flows well due to larger oil path diameter, and lower possibility of leakage.

The machine is also equipped with oil cooling device

Electric system

There is two operation mode:

electric mechanize and semi-automatic

Both of them are controlled by bottom switch.

Working pressure, pressing speed and slide stroke can be set in a certain rang according to different processing requirements.

1. With PLC control

2. 3 operating ways for choice

3. Integral forged 45# steel, quenching and tempering

4. High efficient, convenient and safe operation

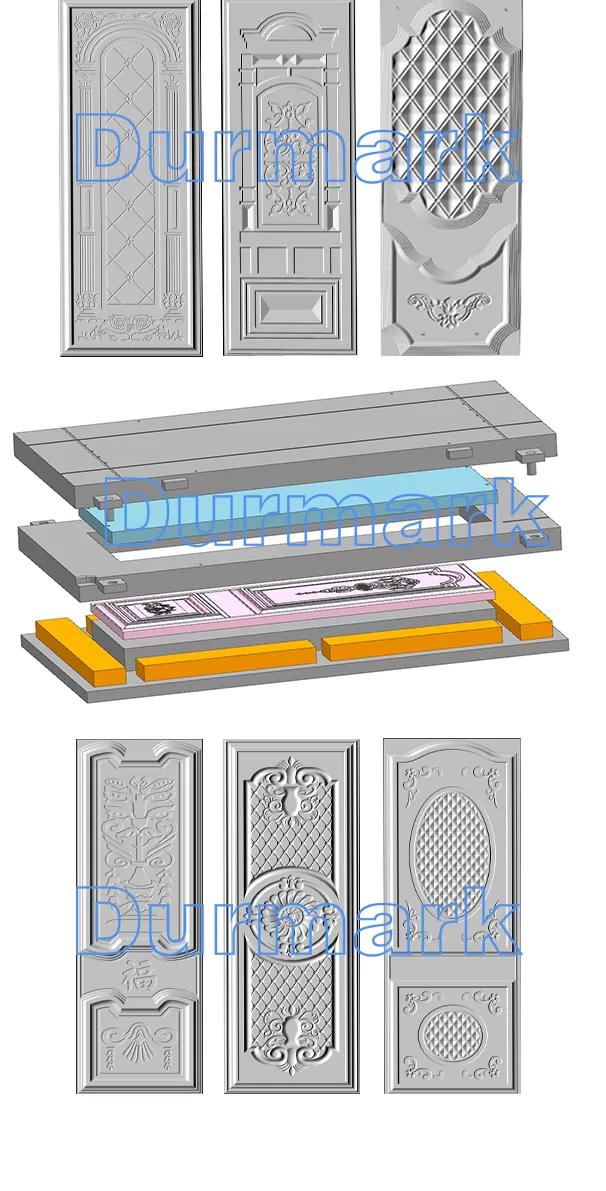

5. Best forming effect, clear 3-dimensional pictorial

6. High quality steel plate welded with accuracy and stability

7. Independent electrical and hydraulic power mechanism

8. Simply structured and well performed for energy saving

9. Available working pressure, speed, and stroke settings

Feature

1.This hydraulic embossing machine is mainly used at security door, steel wooden door, inside door, stainless steel doors, iron gate, etc production factory and steel market, for punching press different pattern security door panel, stainless door panel, inside door panel. This machine’s advantage are high efficient, convenient and safe operating, energy saving, appearance attracting, and low cost.

2.Independent power mechanism and electrical system are controlled by press-button enabling realize manual. And equipped with movable button station. Two operate way : semi-automatic, and automatic operation.

3.Working pressure, speed, and stroke can be set in a certain range according to different technological requirements.

Hydraulic door press machine is mainly for kinds of door skin forming. By changing different moulds to get different designs.