Request a Quote

Request a Quote

Article Directory:

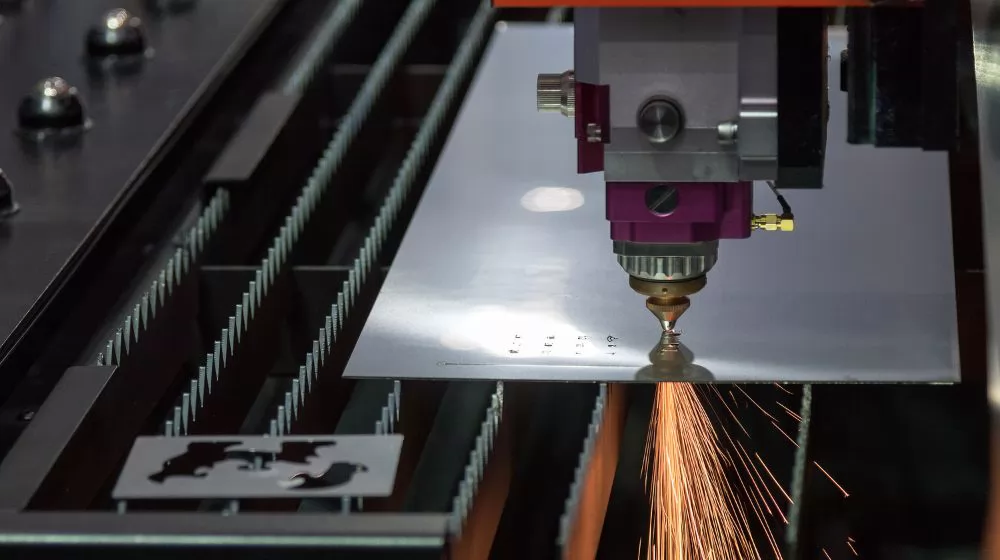

In modern manufacturing industry, fiber laser cutting machine has become a widely used high-efficiency cutting equipment. It has attracted much attention for its high precision, high-speed cutting and multi-material applicability. Whether it is metal or non-metallic materials, fiber laser cutting machines can provide fine and precise cutting results, enabling complex shapes and details to be realized. This article will provide you with valuable information and insights, let's find out together!

Fiber laser cutting machine is a special equipment for precise cutting of optical fiber by laser technology. It uses high-energy-density laser beams to achieve precise cutting effects by pulsed or continuous cutting of optical fibers. Fiber laser cutting machines usually have precise positioning systems and high-speed cutting capabilities, which can cut optical fibers in various shapes and sizes.

fiber laser cutting machine is to use the thermal effect of laser. The laser beam is focused on the surface of the fiber, and the high-energy laser beam instantly heats the fiber to reach the melting temperature of the cutting point. Subsequently, the cutting machine precisely controls the cutting process by controlling the position and time of the laser beam, and realizes the cutting of the optical fiber.

Fiber laser cutting machine is widely used in communication, fiber optic sensing, fiber optic device manufacturing and other fields. It can realize precise cutting of optical fiber, and is used to make optical fiber components such as optical fiber connectors, optical fiber couplers, and optical fiber arrays. In addition, fiber laser cutting machines can also be used to make and repair optical fiber connections, as well as process and customize optical fibers.

The fiber laser cutting machine cuts the optical fiber precisely by laser technology. It works by positioning the fiber, setting the cutting parameters, and then using a high-energy-density laser beam to cleave the fiber. The cutting machine controls the position, time and power of the laser beam, so that the cutting stops after the optical fiber reaches the melting temperature. After the cut is complete, it is time to inspect the cut quality and clean up the work area. The working principle and operation steps of different models of fiber laser cutting machines may be different, and you should refer to the manufacturer's guide for operation.

Laser cutting machine and fiber laser cutting machine are two different types of cutting equipment, which differ in laser source and cutting method.

Laser cutting machines usually use CO2 lasers or solid-state lasers as cutting sources. They use a lens system to focus the laser beam on the workpiece for cutting. Laser cutting machine is suitable for cutting metal and non-metal materials, can handle larger material thickness and area, and is widely used in industrial fields.

The fiber laser cutting machine uses fiber laser as the cutting source, and transmits the laser beam to the cutting head through the optical fiber. The fiber laser cutting machine has small size and flexibility, and can achieve high-precision and high-speed cutting. It is widely used in optical fiber materials, optical fiber devices and other fields.

Laser cutting machines are suitable for a wider range of material cutting, including metal and non-metal materials, while fiber laser cutting machines are more focused on cutting and processing fiber optic materials. Choosing the right cutting machine requires consideration of factors such as material type, cutting requirements and budget.

It is necessary to comprehensively consider the advantages and disadvantages of fiber laser cutting machines according to specific application requirements and material characteristics to determine whether it is suitable to use fiber laser cutting machines for cutting and processing.

Advantage:

High precision: The fiber laser cutting machine has high cutting precision and positioning precision, which can realize precise cutting and processing.

High-speed cutting: The fiber laser cutting machine has high-speed cutting capability, which can quickly complete cutting tasks and improve production efficiency.

Non-contact cutting: The fiber laser cutting machine adopts a non-contact cutting method without direct contact with the workpiece, reducing the possibility of material deformation and cutting tool wear.

Flexibility: The fiber laser cutting machine is suitable for cutting and processing a variety of materials, including metal and non-metal materials, and has a wide range of application fields.

Smaller heat-affected area: The fiber laser cutting machine can quickly heat the material locally to the melting or evaporation point through the high energy density of the laser, reducing the heat-affected area and helping to maintain the quality of the cutting edge.

Shortcoming:

High cost: Compared with traditional cutting equipment, fiber laser cutting machine has higher price and higher investment cost.

High requirements on optical fiber: Fiber laser cutting machines have high requirements on optical fiber quality and stability, and require regular maintenance and replacement of optical fibers, which increases operating costs and maintenance workload.

Not suitable for all materials: Although fiber laser cutting machines are suitable for a variety of materials, for some special materials such as transparent materials or highly reflective materials, the cutting effect may be limited.

Fiber laser cutting machines can cut a variety of materials, including fiber optic materials, metal materials, non-metal materials and other special materials.

Fiber laser cutting machines are often used in the field of fiber processing, which can precisely cut optical fibers, fiber gratings, etc. At the same time, some fiber laser cutting machines also have the function of metal cutting, which can cut metal materials such as stainless steel and aluminum alloy. In addition, fiber laser cutting machines are also suitable for cutting non-metallic materials such as plastics, wood, acrylic, leather, and rubber.

For special materials such as ceramics, stone, fiberglass, etc., special processes and configurations may be required. Material type, thickness, and cutting requirements need to be considered when choosing the right fiber laser cutting machine

The thickness that a fiber laser cutting machine can cut depends on the power of its laser source and the type of fiber. The specific cutting thickness range will vary according to different fiber laser cutting machine models and configurations.

For finer cutting requirements, it is usually necessary to use a higher power laser source and a professional fiber laser cutting machine. When choosing a fiber laser cutting machine, you should refer to the technical specifications and instructions provided by the manufacturer to determine its applicable cutting thickness range.

Fiber laser cutting machines are widely used in many different fields, including but not limited to the following:

Metal processing: Fiber laser cutting machines have important applications in the field of metal processing and can be used to cut various metal materials, such as stainless steel, aluminum alloy, carbon steel, etc. It can be applied in metal fabrication, auto parts, aerospace and other industries.

Optical fiber manufacturing: Fiber laser cutting machines play a key role in the optical fiber manufacturing industry and are used to process optical fiber devices such as cutting optical fibers and fiber gratings.

Electronic equipment manufacturing: Fiber laser cutting machines are widely used in the field of electronic equipment manufacturing, and can be used to cut circuit boards, wires, electronic components and other tiny parts.

Equipment manufacturing: fiber laser cutting machine can be used in medical equipment, precision instruments and other equipment manufacturing fields to achieve high-precision cutting and processing of various materials.

Handicrafts and decoration: fiber laser cutting machine can cut various non-metallic materials, such as acrylic, wood, leather, etc., and is widely used in handicrafts, decoration production and advertising industry.

Automobile and shipbuilding: Fiber laser cutting machines have important applications in automobile and shipbuilding, and can be used to cut metal sheets, parts and body structures.

When choosing the size and power of the cutting machine, it is recommended to consult with the supplier or manufacturer in detail, and understand its technical specifications and performance parameters. According to specific application requirements and budget constraints, consider several factors and choose the most suitable cutting machine size and power :

Cutting material type and thickness: first determine the material type and thickness range to be cut. Different materials and thicknesses have different requirements on the cutting machine, so it is necessary to choose the appropriate size and power of the cutting machine.

Cutting speed and production demand: According to the expected cutting speed and production demand, choose a cutting machine with a corresponding cutting speed. Cutting speed is related to power, usually higher power can provide faster cutting speed.

Working Space and Material Size: Choose the right cutting machine size considering the available working space and the size of the material to be cut. Make sure the cutting machine can accommodate and handle the required workpiece size.

Budget and investment cost: According to the budget limit and investment cost, determine the acceptable cutting machine price range. The prices of cutting machines of different sizes and powers will vary.

Expected cutting quality and precision: Consider the expected cutting quality and precision requirements, and choose a cutting machine with the corresponding precision. High-precision cutting usually requires higher machine accuracy and stability.

According to the maintenance manual and recommendations provided by the manufacturer, follow the correct operating procedures and safe operation requirements, and perform regular equipment inspection and maintenance, which can help ensure the normal operation and long-term reliability of the fiber laser cutting machine. Here are a few main points to maintain:

Regular cleaning: Regularly clean the working area and optical components of the cutting machine, including lenses, mirrors, etc. Use proper cleaning agents and tools to ensure no accumulation of dust and grime.

Optical fiber maintenance: Optical fiber is the core component of fiber laser cutting machine, which requires regular inspection and maintenance. Make sure that the fiber optic connections are good, free from damage, and not bent or subjected to excessive tension.

Cooling system maintenance: Fiber laser cutting machines usually use a cooling system to reduce the temperature of the laser and optical components. Regularly check the coolant level and quality of the cooling system, and clean the cooler and filter.

Optical system calibration: Regularly check and calibrate the optical system to ensure the accuracy and stability of the laser beam focus point.

Power adjustment and alignment: maintain the stability of the laser power adjustment and alignment system to ensure that the output power meets the requirements.

Protective lens replacement: According to the usage, check and replace the protective lens regularly to maintain the cutting quality and the protection of optical components.

Keep a Maintenance Log: Record dates and details of maintenance operations, troubleshooting and replacement parts to track maintenance history and preventative maintenance.

The main reason for using a fiber laser cutting machine to cut materials is its advantages such as high precision, high-speed cutting, non-contact cutting and multi-material applicability. The fiber laser cutting machine can achieve precise cutting lines and cutting of complex shapes with extremely high cutting accuracy. Its fast cutting capability increases productivity, while non-contact cutting avoids material deformation and cutting tool wear.

The fiber laser cutting machine is suitable for a variety of materials, including metal and non-metal materials, and can be adjusted according to the characteristics of different materials to achieve high-quality cutting results. In addition, fiber laser cutting machines have a small heat-affected zone and are suitable for workpieces of various shapes and sizes, providing flexibility.

Fiber laser cutting machines not only provide efficient and precise cutting solutions for all walks of life, but also create unlimited possibilities for innovation and development. I hope this article can provide you with comprehensive and valuable information, and provide you with some guidance and inspiration in the journey of exploration and application of fiber laser cutting machines. If there is still something you don't understand, please contact us!

.png)