Request a Quote

Request a Quote

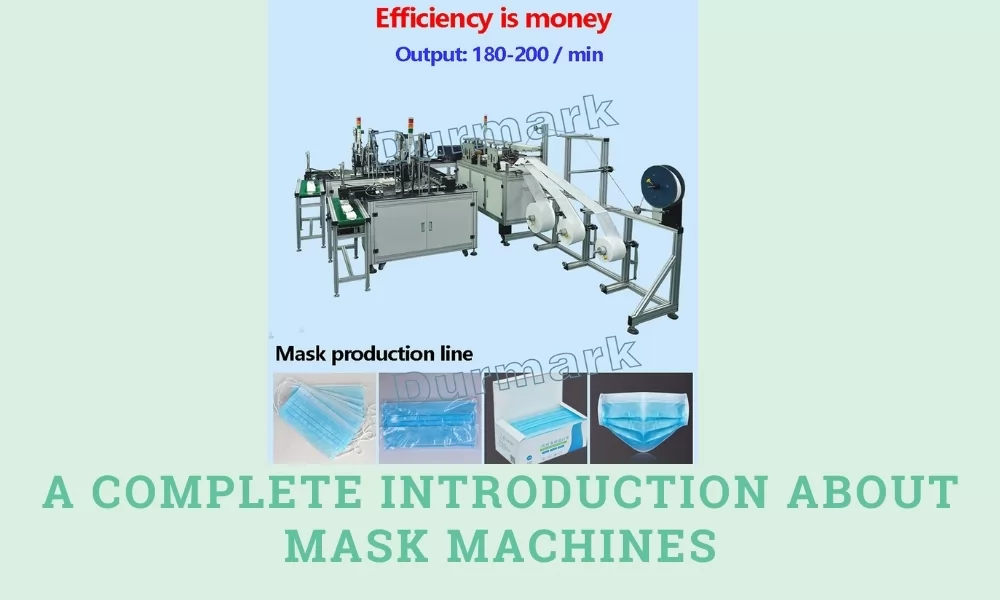

The mask machine is to make various masks with certain filtering performance through the processes of hot pressing, folding and forming, ultrasonic welding, waste removal, ear band and nose strip welding. The mask production equipment is not a single machine. It requires the cooperation of multiple machines to complete various processes.

Automatic cup mask machine

The adopted advanced servo and constant temperature control system is controlled by PLC program to make the material enter→forming→welding→punching completed at one time, and the whole production process is fully automated.

The equipment only needs to be equipped with a fully automatic cup-shaped mask nose bridge strip and ear strap welding machine, and it can produce countless cup-shaped mask products that are sold in the market.

The products are exquisitely made and the quality fully meets or exceeds domestic and foreign testing standards. At the same time, it saves more than 30% of the materials used for mask equipment in the previous market. Thereby realizing the reduction of costs and the improvement of efficiency in a true sense.

n95 cup mask machine

Hot press molding: the mask raw material (non-woven fabric) is molded with the form of overheating (cup-shaped). 1. With automatic return action and feeding rack; 2. One piece of four masks is formed each time.

Slicing: used to make the outer layer (protective layer) of cup-shaped masks. Special alloy steel material makes the flower wheel, the knife edge is wear-resistant and the long-life product is eccentrically adjusted, flexible, fast and high-level. Utilizes ultrasonic and special steel Wheel processing, does not damage the edge of the cloth, no preheating is required when manufacturing without burrs, and can be operated continuously

Edge pressing: Laminate the inside and outside of the mask

Edge trimming: Use pneumatic punching to cut off the excess edges of the mask.

Breathing valve welding: welding mask breathing valve

Welding area: 130mm

Speed: 45 pcs/min

The fuselage has an integrated structure and adopts safe adjustment scale control; computer intelligent control, with an accuracy of up to one thousandth of a second; mold level adjustment, the fuselage motor automatically rises and falls, and the base level is adjusted.

Ear band spot welding machine: Speed: 8-12 pieces/min. It can be used for welding flat, inner ear band/outer ear band, standard mask, duckbill and other special-shaped masks. After the mask body is made, the ear straps are welded manually

Flat strap mask machine

Ultrasonic mask banding machine adopts ultrasonic welding method. A conveying device is installed on the machine. The semi-finished mask is fed into the conveying device. After the edge of the drawing tube, the band is pressed by the ultrasonic flower wheel, and the band is cut to output the finished product. One person needs to place the mask body on the conveyor belt of the machine, and the rest of the follow-up work is completed automatically.

Bandage mask machine

Bandage mask machine

Features of Ultrasonic Mask Banding Machine:

1. The frame is made of aluminum alloy and stainless steel, and the appearance is light and beautiful without rust.

2. Automatic counting, which can effectively control production efficiency and production progress.

3. Frequency conversion control can adjust the operating speed of the equipment according to actual needs.

4. Pull the barrel to feed the material, the positioning is more accurate, the width of the raw material can be controlled to the minimum, and the cost is saved.

5. The length and size of the finished product are uniformly controlled, with a deviation of ±1mm, which can effectively control the length of the finished product.

6. The equipment has a high degree of automation and low requirements on the operating staff. It only needs to discharge the materials and arrange the finished products.

7. This machine adopts ultrasonic Taiwan system, Japanese transducer, stable performance and convenient operation.

8. The automatic ultrasonic welding wheel is made of imported high-quality steel DC53, which prolongs the life of the mold and is wear-resistant and durable.

Flat outer ear mask machine

The outer ear mask machine ultrasonically fuses the elastic bands on the outer sides of the mask body to complete the earband mask product. Only one operator needs to place the mask body piece by piece on the conveyor belt jig, and the rest of the subsequent actions are completed to the finished product. All are automatically operated by the machine, and the output of this machine is higher than that of ordinary earband machines.

Ultrasonic plane ear mask machine

Ultrasonic plane ear mask machine

Parameters of ultrasonic plane outer ear mask machine:

Machine size: 2646(L)*620(W)*1750(H)m/m

Voltage: Single-phase 220V

Output: 45-55pcs/min

Air pressure: 6kg/cm2

Power consumption: 3KW

The size of the mask body must be fixed

Features of the ultrasonic plane outer ear mask machine:

1. The machine is compact, small in size, and does not take up space;

2. PLC program control, high stability, low failure rate;

3. The whole machine adopts aluminum alloy structure, which is beautiful and firm without rust;

4. Photoelectric detection reduces the error rate.

5. The welding strength of the ear straps is adjustable.

In modern society, due to the continuous deterioration of the natural environment and the strengthening of people's awareness of protection, the market demand for disposable medical masks and protective masks is constantly expanding. Many customers are keenly aware of this business opportunity and want to get involved in the mask production industry. However, in view of the unfamiliarity with the mask production process, the purchase of mask raw materials, the selection of mask machine manufacturers, the planning of mask production workshops, the industry standards for mask production, etc., when inquiring about and consulting relevant information and making relevant budgets, Looks very blind and confused. The following are some common-sense introductions to the ultrasonic mask machine to help customers who are ready to show their skills in the mask production industry to open a little light in the mist and know where the direction is:

First of all, masks are simply divided into flat masks and three-dimensional masks in terms of appearance. Flat masks are mostly used in the medical industry, and three-dimensional masks are mostly used for daily protection. This article is mainly for the purchase of ultrasonic flat mask machine (ultrasonic medical mask machine).

Secondly: The flat mask machine series can be divided into: inner ear mask machine production line, outer ear mask machine production line, band mask machine production line according to the welding method and use method of the ear belt.

Our company has a variety of automatic mask machines with low price and high quality, which can meet the various needs of our customers. Everyone is welcome to come to us for selection and purchase. This is our website: https://www.durmark-machinery.com/mask-making-machine/

.png)