Request a Quote

Request a Quote

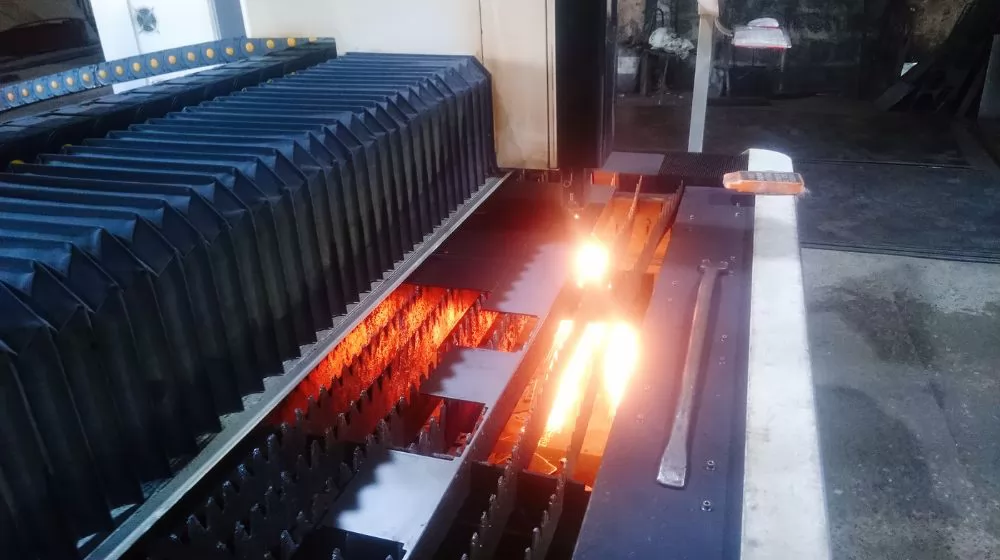

In terms of purchasing laser cutting machines, facing the mixed laser market, many laser cutting machine manufacturers focus on price competition. It makes customers more and more confused, so how much does a laser cutting machine cost?

Laser cutting equipment is mainly divided into fiber laser cutting machine, crystal laser cutting machine and CO2 laser cutting machine. Although they are all laser cutting equipment, their prices are different. Even for the same product, the price is different. What are the factors that affect the cost of laser cutting machine?

In this article you will learn:

Factors affecting price

Write in the end

If you are clear about your needs, you can directly choose to know the price of laser cutting machine.

Before you look at a part, please think about what do you need to make, what do you need to accomplish?

Without a laser cutting machine, you can of course find a suitable processor to do it for you, as long as your order time is flexible enough. But have you considered these questions:

How many times have we lost business because of late deliveries?

Have we ever had to reject parts because of poor quality?

How does it help our image if we have our own laser cutting capabilities?

How much more productive is the manufacturing process with laser cutting?

How does using a laser cutter affect lead times?

What are the cost of laser cutting machine

As the industry develops and competition gradually intensifies, we must introduce you to the development trend of laser cutting machines to understand the challenges and possible opportunities in the future.

The compound growth rate of the laser industry will reach more than 20% in the next three years.

The replication of the successful experience of low-power cutting in the high-power field is the biggest driving force in the future.

The sales growth rate of laser cutting control system is expected to exceed 30% in the next three years.

Laser cutting technology will be more diversified in the selection of generators, the power supply types of generators will be more diversified, the energy output will be more stable, and the cost of using laser cutting machines will be significantly reduced. The harm to the human body will also be greatly reduced.

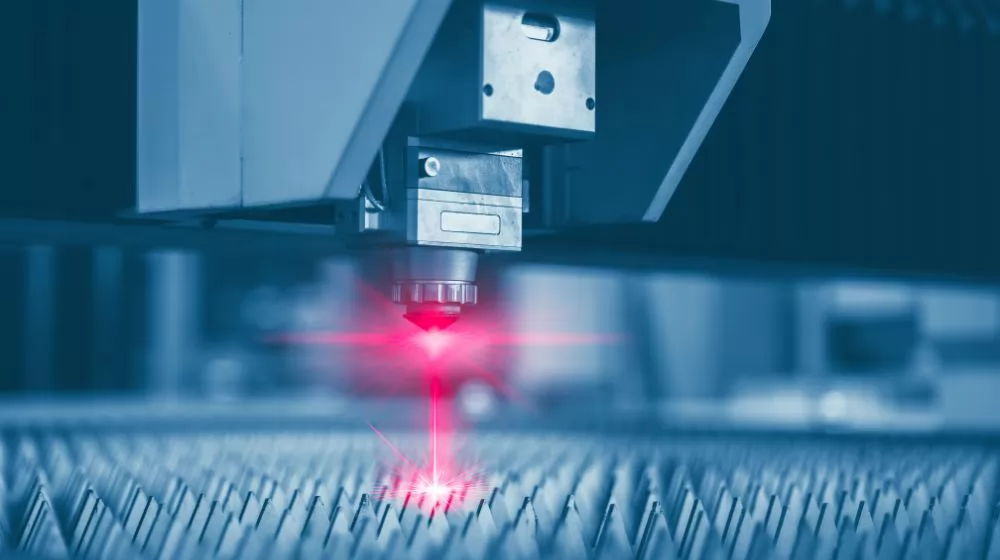

CO2 laser cutters consist of a mixture of CO2 gas and other gases such as helium and nitrogen. This type of gas mixture is charged by a discharge, which then produces a laser beam. The wavelength of this cutter is 10.6mm.

CO2 laser cutters are the most common and prestigious because they are efficient and inexpensive.

Materials: glass, plastic, leather, wood and acrylic.

Crystal laser cutters generate beams from yttrium orthovanadate doped with neodymium. These cutters have a smaller wavelength than CO2 laser cutters, so they can cut some thicker materials.

Smaller wavelengths also contribute to better focus and higher intensity. One of the disadvantages of these knives is that their parts can wear out due to high power functions.

The origin of the fiber laser is a seed laser, which uses a special fiber for amplification. Fiber laser cutting machines are more commonly known as solid-state lasers.

Notable advantages of this laser cutter include cutting reflective and conductive metals, three times more efficiently than CO2 laser cutters, and having no moving parts.

Fiber lasers can be used on metals and organic materials. Although fiber laser cutting machines are very similar to crystal lasers, they are more efficient and less expensive to maintain.

First of all, we must make it clear that the price of a laser cutting machine is affected by many factors such as function, specification, quality, origin, etc. The specific price we provide is for your reference only.

For metal laser cutting machines, the price ranges from $2500.00 to $300000.00

For non-metal laser cutters, the price range is from $2200.00 to $9900.00

For a hybrid laser cutter, the price range is from $4000.00 to $16000.00

People who are familiar with laser cutting machines lament that the configuration of laser cutting machines has improved so much now, and the price has dropped compared with a few years ago, how gratifying. But now some say, don't be fooled by all those outward things, if compared to the reliability of many new devices and the ease and affordability of repair services a few years ago. In my opinion, users should pay more attention to the cost performance of laser cutting machines. The laser cutting machine with "proper configuration and moderate price" is our best choice. Many users fall into this misunderstanding. They hope that the laser cutting machine they buy is "all-round". The laser machine can do everything, which is actually wrong.

The above are the six factors that affect the cost of laser cutting machines. What kind of cutting machine should be customized according to your own needs and budget, and the thickness of the cutting material can be determined according to the specific power requirements.

In order to reduce costs, some manufacturers use thin iron sheets to make machine casings. Some users don't normally see them. But after a long time, the rack will be deformed, which will affect the cutting accuracy of the laser cutting machine. A good laser cutting machine should adopt a frame structure, welded with high-quality steel, and the shell is made of high-quality cold-rolled steel. When the user purchases the machine, the quality can be judged by the frame structure, the thickness and strength of the shell iron.

Similarly, laser cutting machines use different components, such as lasers, motors, laser lenses, laser tubes, and control systems, which will affect the price of laser cutting machines. STYLECNC gives an example:

A. Motor

The motor is related to the precision of the laser cutting machine, and the cost of a famous brand motor is different from that of an ordinary brand motor. Laser cutters will also vary in precision.

B. Laser lens

The laser lens is related to the power of the laser cutting machine. The price gap is very large, and the effect and service life are also very different.

C. Laser tube

This is the heart of the laser cutter. The brand and quality of laser tubes are different, and the prices are also different. The service life of a good laser tube is usually around 3000 hours.

Different models of the same factory (different laser power and different cutting methods) will have different prices. Users need to choose the most suitable power and format according to their needs in order to make the best use of everything and bring more value to the enterprise. high returns.

Fiber laser cutting machine, crystal laser cutting machine and CO2 laser cutting machine have different cutting quality and speed, and the price is also different.

When purchasing large laser equipment, after-sales service is a key issue.

Successful delivery and installation requires preparation. First, what type of foundation (if any) is needed? Second, the laser cutter must be located in the correct location in the facility, preferably away from harsh environment areas. You should also find the sweet spot for the laser so that it facilitates the efficient flow of the laser-cut blank to the downstream manufacturing process.

Full service to ensure the safety and timely maintenance of user equipment. The laser tube and reflector of the laser cutting machine are all consumables, which have a certain service life and need to be replaced after expiration. This requires manufacturers to provide strong after-sales service guarantees and provide these consumables in a timely manner. Different manufacturers have their own advantages and disadvantages in after-sales service. So the price will be different.

JMT (USA)

Durmark (China)

SLTL (India)

NUKON US (USA)

G WEIKE (China)

ALPHA LAZER (Canada)

ACCURL (China)

TRIUMPH (China)

OREE LASER (China)

DXTECH (China)

Read more: List of Top 10 Laser Cutting Machine Manufacturers

You can narrow down your choice of laser cutting machine suppliers based on your budget and needs and make a suitable comparison.

You should find the right model, conduct detailed research and ask questions of your target partners. Then get an acceptable price.

If you are looking for a suitable laser cutting machine, welcome to contact us. Durmark is a well-known laser cutting machine manufacturer and sheet metal machine manufacturer in China, providing user-friendly solutions to customers all over the world. If you want to know more product information, welcome to click laser cutting machine or contact us.

.png)