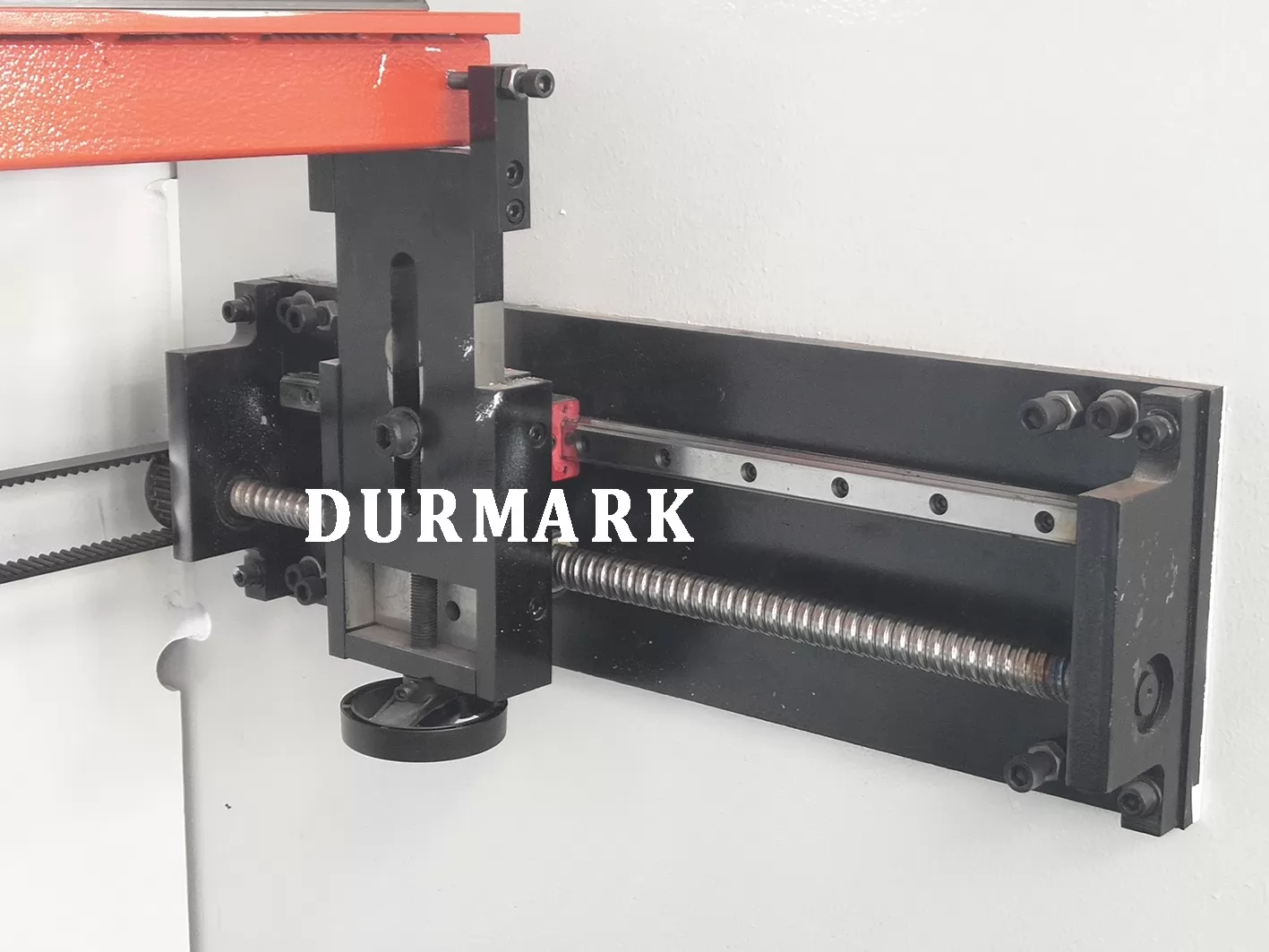

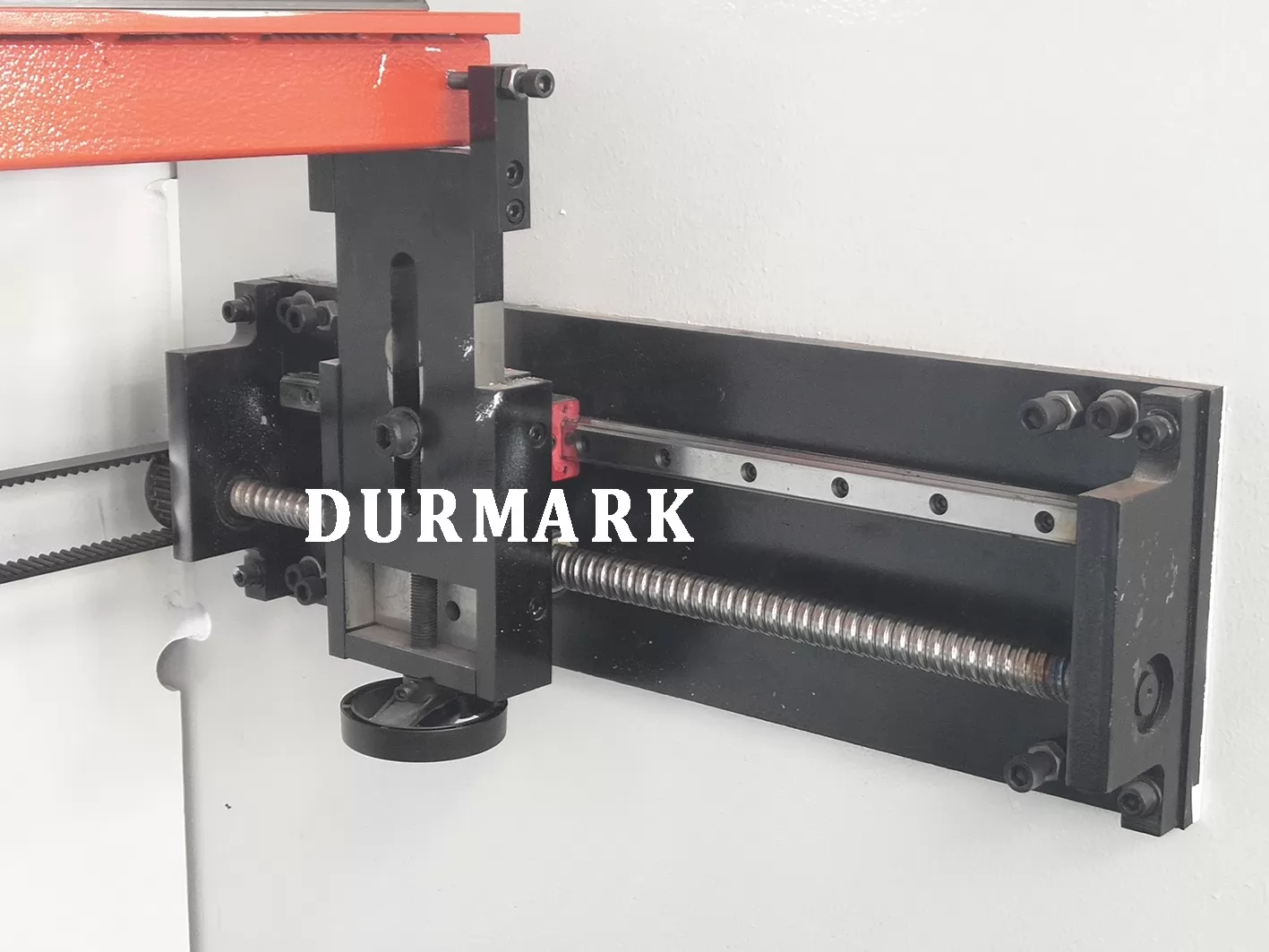

Durmark company creates Mini bending machine(press brake)in an all-round way, which is convenient for customers to process different products

The effect of this kind of small bending machine is really different

Durmark, as the first one in China, is engaged in the design of bending machine and the design, development and production of numerical control back stop of bending machine. Thank you for your support and trust to me and our company. Our team has sufficient experience and qualification. We have experience and obligation to give you a detailed introduction of the knowledge and attention points of common bending machine and upgrading numerical control. If there is something wrong, please correct it.

Durmark, as the first one in China, is engaged in the design of bending machine and the design, development and production of numerical control back stop of bending machine. Thank you for your support and trust to me and our company. Our team has sufficient experience and qualification. We have experience and obligation to give you a detailed introduction of the knowledge and attention points of common bending machine and upgrading numerical control. If there is something wrong, please correct it.

First of all, to introduce the common bending machine processing problems?

1. The repeated positioning accuracy of the common bending machine is not high, which requires line drawing and bending, so the efficiency is very low.

For multi-step bending, the error is also large, which is not suitable for mass production.

3. The angle control error of common bending machine is large, and it is difficult for workers to adjust the angle.

4. The common bending machine often bumps the mold, so it is troublesome to fold the reverse knife, and the back baffle cannot be lifted up and down.

5 bending machine has a great error in back blocking, and the positioning time of simple CNC bending machine system is long

6 bending workers are difficult to recruit, bending efficiency is too slow, line drawing and bending are highly required for workers.

7. The material calculation of ordinary bending machine is complex, which requires more workers.

8. The bending machine comes down directly without pause, which is very unsafe.

9. The fingers of the crossbeam behind the bending machine can not move left and right, or the error is large.

10. Connect the neutral wire to PE randomly, not a single power supply, insufficient protection level of electrical cabinet, insufficient protection of electrical equipment, hidden danger of control line, incomplete safety operation protection function, incomplete warning signs

Then, durmark bending machine(E21 cnc system):

Repeated positioning accuracy: 0.1-0.15mm

Actual bending accuracy: 0.2-0.4mm

Angle error of both sides: ± 3-4 °

Your email address will not be published. Required fields are marked *

Durmark, as the first one in China, is engaged in the design of bending machine and the design, development and production of numerical control back stop of bending machine. Thank you for your support and trust to me and our company. Our team has sufficient experience and qualification. We have experience and obligation to give you a detailed introduction of the knowledge and attention points of common bending machine and upgrading numerical control. If there is something wrong, please correct it.

Durmark, as the first one in China, is engaged in the design of bending machine and the design, development and production of numerical control back stop of bending machine. Thank you for your support and trust to me and our company. Our team has sufficient experience and qualification. We have experience and obligation to give you a detailed introduction of the knowledge and attention points of common bending machine and upgrading numerical control. If there is something wrong, please correct it.

.png)