Request a Quote

Request a Quote

Table of contents:

In the world of metal fabrication, precision bending is a fundamental process that shapes raw materials into intricate forms. Two key players in this domain, the Press Brake and the Finger Brake, offer unique capabilities for bending metal sheets to desired specifications. While both serve as essential tools in metalworking, they possess distinct characteristics that cater to different bending requirements. This article delves into the intriguing comparison between the Press Brake and the Finger Brake, shedding light on their individual strengths, applications, and the factors that influence their selection. By understanding the differences between these two bending techniques, we gain insight into how each contributes to the realm of manufacturing.

In manufacturing, bending is a common and important process used to process metal materials, plastics or other bendable materials into desired shapes and angles. This processing method usually applies force to bend and deform the material in order to manufacture various parts, products and components. So at this time, bending machinery is needed to realize it, such as press brake and finger brake.

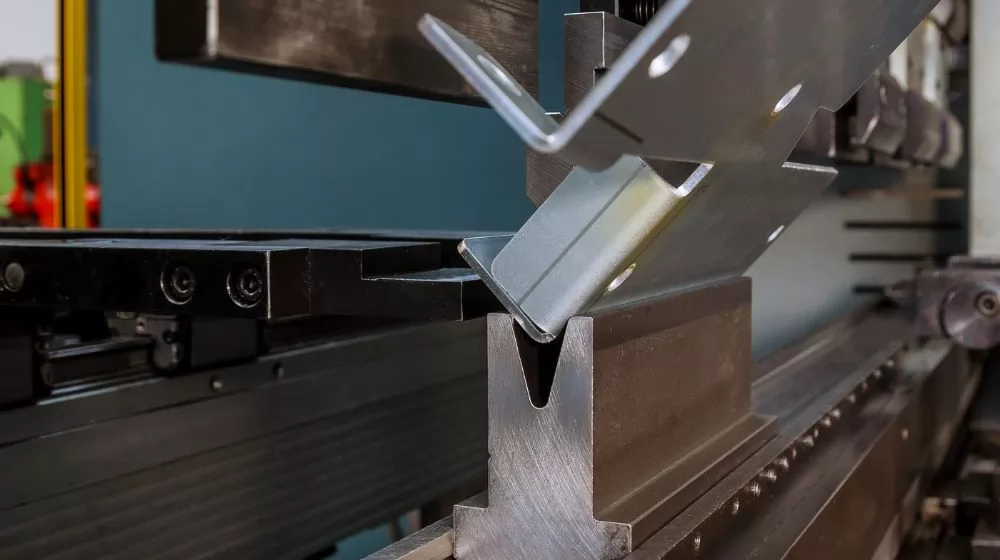

A Press Brake is a mechanical device used for bending metal sheets in metalworking processes. It finds widespread application in the manufacturing industry, particularly in the field of metal fabrication. The Press Brake functions by applying pressure to bend_1692340948_WNo_800d533.webp) metal sheets into desired shapes such as V-shapes, U-shapes, and angles, enabling the production of various products like metal components, mechanical parts, and vehicle body parts.

metal sheets into desired shapes such as V-shapes, U-shapes, and angles, enabling the production of various products like metal components, mechanical parts, and vehicle body parts.

Press Brakes play a crucial role in the manufacturing industry, enabling high-precision metal bending processes suitable for projects of varying scales, from small-batch customizations to large-scale production. Moreover, with the advancement of automation and digital technologies, some Press Brakes are equipped with automation features, capable of performing bending processes automatically through pre-set programs, thereby enhancing production efficiency and consistency.

Clamping the Material: Firstly, place the metal sheet to be processed onto the working area of the Press Brake and clamp it between the upper die and lower die to ensure stability during the bending process.

Selecting the Tooling: Depending on the desired bending angle and shape, select appropriate upper and lower dies (also referred to as top tooling and bottom tooling). The shapes of these dies determine the final bending form of the metal sheet.

Applying Force: Employ hydraulic, mechanical, or electric power systems to apply force perpendicular to the metal sheet, causing it to bend. In this process, the upper die presses down on the lower die, causing the metal sheet to deform through bending.

Bending Angle Control: Modern Press Brakes are often equipped with numerical control (CNC) technology, enabling precise control over the applied force and bending angle. Operators can preset the desired bending angle and depth, making the processing more precise and controllable.

Material Bending: As the applied force increases, the metal sheet begins to bend along the contour of the die until the desired bending angle is achieved.

Material Release: Once the bending process is complete, release the applied force on the metal sheet. The upper and lower dies will separate, allowing the operator to retrieve the completed bent metal workpiece.

Versatility: Press Brakes are highly versatile tools that can bend a wide range of materials, including metals like steel, aluminum, and stainless steel, as well as plastics. This versatility makes them suitable for diverse industries and applications._1692341007_WNo_800d533.webp)

Precision Bending: Modern Press Brakes equipped with CNC technology allow for precise control over bending angles, depths, and dimensions. This level of accuracy ensures consistent and high-quality results, meeting tight tolerances required by many industries.

Efficiency: Press Brakes can efficiently bend large volumes of materials in a relatively short time, contributing to improved production efficiency. CNC controls enable automated bending sequences, reducing manual intervention and increasing productivity.

Complex Shapes: With the aid of specialized tooling and CNC programming, Press Brakes can create intricate and complex shapes, meeting the demands of intricate designs and custom components.

Repeatable Results: CNC-controlled Press Brakes ensure that each bending operation is replicated accurately. This repeatability is essential for mass production and maintaining consistent product quality.

Reduced Waste: Precise bending reduces material waste by minimizing errors and rework. This is particularly significant when working with costly materials.

Cost Savings: By automating bending processes and reducing the need for manual labor, Press Brakes contribute to cost savings over time. The accuracy of CNC controls also reduces material wastage and rework costs.

Flexibility: Press Brakes can handle both simple and complex bending tasks, offering flexibility to manufacturers with varying project requirements.

Safety: Modern Press Brakes are designed with safety features such as light curtains and interlocking guards to prevent accidents and protect operators.

Customization: CNC programming allows for easy adjustment and customization of bending sequences, enabling quick adaptations to design changes.

Adaptability: Press Brakes can be adapted for different bending tasks by changing tooling and adjusting settings, making them suitable for a wide range of projects.

Sheet Metal Fabrication: Press Brakes are extensively used in sheet metal fabrication to create components for industries such as automotive, aerospace, electronics, and appliances. They can form intricate shapes and angles required for various parts.

Automotive Industry: In the automotive sector, Press Brakes are used to manufacture body panels, brackets, frames, and other components that require precise bending to meet safety and structural requirements.

Aerospace Industry: Aerospace applications involve forming complex shapes for aircraft components, such as wing structures, fuselage sections, and engine components.

Construction and Architecture: Press Brakes are employed to create architectural components like stair railings, decorative panels, and structural elements used in building construction.

Furniture Manufacturing: Press Brakes are used to create metal components for furniture, including frames, brackets, and decorative elements.

Industrial Equipment: Many industrial machines and equipment require custom bent components for structural support and functionality.

Appliance Manufacturing: Press Brakes are used in the production of household appliances, forming parts like refrigerator shelves, washing machine drums, and oven components.

Pipe and Tube Bending: Press Brakes can be adapted with special tooling to bend pipes and tubes for applications in plumbing, HVAC systems, and fluid transportation.

Electronics Industry: In electronics manufacturing, Press Brakes are used to create chassis, enclosures, and brackets for electronic devices.

Energy Sector: Press Brakes play a role in manufacturing components for renewable energy systems, such as solar panel frames and wind turbine components.

Shipbuilding: Press Brakes are employed in shipbuilding to create structural components and ship parts that require precise bending to ensure the vessel's integrity.

Custom Fabrication: Press Brakes are essential for producing custom components for specialized applications that require unique shapes and sizes.

A Finger Brake, also known as a Box and Pan Brake, is a type of metalworking machine used for bending sheet metal and other thin materials. It is particularly useful for creating various box-like shapes, pans, and trays, which may have multiple bends and flanges. Finger Brakes are commonly used in industries like metal fabrication, HVAC (Heating, Ventilation, and Air Conditioning), and general manufacturing.

flanges. Finger Brakes are commonly used in industries like metal fabrication, HVAC (Heating, Ventilation, and Air Conditioning), and general manufacturing.

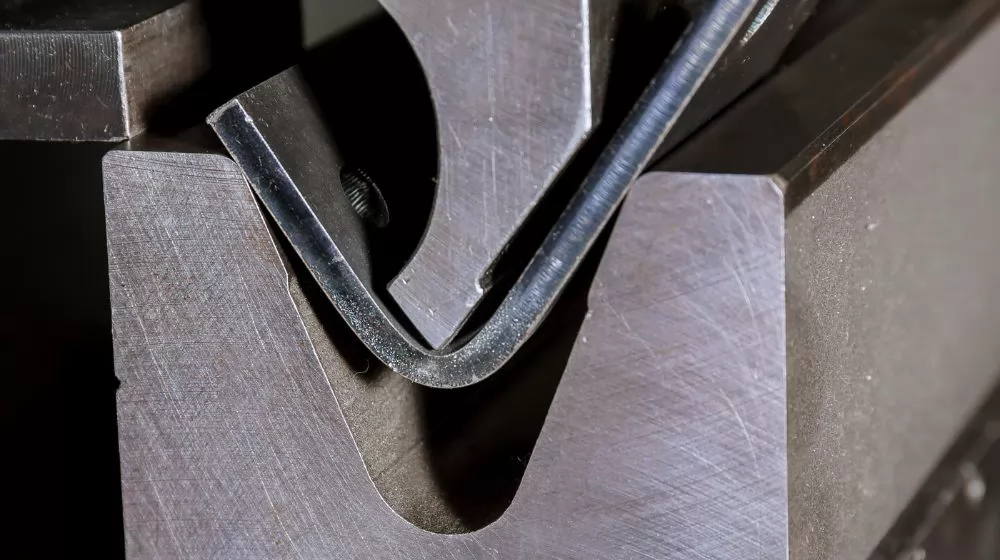

The distinguishing feature of a Finger Brake is its set of segmented "fingers" or adjustable bars located on the upper beam of the machine. These fingers can be adjusted and positioned independently to create the desired bending angles and shapes in the workpiece. By manipulating the finger positions, operators can achieve intricate bends, flanges, and boxes with different dimensions and angles.

Adjustable Fingers: A Finger Brake is equipped with a set of adjustable fingers or segmented bars on the upper beam of the machine. These fingers can be moved and positioned independently to create different bending angles and shapes.

Material Placement: The sheet metal to be bent is placed between the adjustable fingers and the lower bed of the machine. The fingers are aligned with the bending lines marked on the sheet metal.

Bending Process: The upper beam, which holds the adjustable fingers, is lowered towards the lower bed of the machine. As it descends, the fingers come into contact with the sheet metal. The sheet metal is pressed between the fingers, causing it to bend along the chosen bending lines.

Controlled Bending: By adjusting the positions of the individual fingers, operators can control the depth and angle of the bends in the sheet metal. This enables the creation of various shapes, including boxes, pans, and trays, with precise dimensions and angles.

Multiple Bends: Finger Brakes are particularly useful for creating multiple bends in a single piece of sheet metal. The adjustable fingers allow for the formation of flanges, creases, and intricate shapes in the material.

Release and Removal: After the bending process is complete, the upper beam is raised, releasing the pressure on the sheet metal. The bent sheet metal can then be removed from the machine.

Versatile Bending: Finger Brakes excel in creating a variety of box-like shapes, pans, trays, and other intricate forms that involve multiple bends and flanges. They provide the flexibility needed for diverse bending requirements.

Multiple Bends in One Setup: Finger Brakes allow for multiple bends to be made in a single setup, saving time and increasing efficiency compared to traditional single-bend processes.

Adjustable Fingers: The adjustable fingers on the upper beam provide precise control over the bending angles and dimensions. This adaptability enables operators to achieve custom shapes and designs with accuracy.

Complex Shapes: Finger Brakes can create complex shapes and geometries that might be challenging or impossible to achieve with regular press brakes or manual methods.

Cost-Effective: For projects involving intricate shapes and multiple bends, Finger Brakes can be more cost-effective and time-saving compared to other bending methods that require specialized tooling or setups.

Minimal Tooling Changes: Changing the finger positions allows for rapid adjustments between different bending operations, reducing downtime and increasing productivity.

Small Workpiece Flexibility: Finger Brakes are ideal for bending small workpieces that may be too intricate or delicate for larger press brakes.

Ease of Use: Operating Finger Brakes requires minimal training, making them suitable for various skill levels in a fabrication workshop.

Less Material Waste: The precise control offered by Finger Brakes reduces material wastage as it minimizes errors and rework during bending operations.

Customization: Finger Brakes enable customization of bends and shapes, making them valuable for producing unique components for specific applications.

Space-Saving Design: Finger Brakes are often compact in design, making them suitable for workshops with limited space.

Suitable for Thin Materials: Finger Brakes are particularly well-suited for bending thin-gauge materials without causing excessive deformation or damage.

Box and Tray Fabrication: Finger Brakes are extensively used in creating various box-like shapes, trays, containers, and boxes, often requiring multiple bends and flanges.

Ductwork and Ventilation: In the HVAC (Heating, Ventilation, and Air Conditioning) industry, Finger Brakes are employed for manufacturing ductwork and ventilation components to suit different airflow requirements.

Electrical Enclosures: Finger Brakes are utilized to fabricate enclosures and components for electrical equipment, such as control boxes and switch enclosures.

Signage and Display Racks: Finger Brakes are suitable for crafting signage, display racks, and cabinets with different shapes and sizes to meet specific requirements.

Metal Artwork: Finger Brakes are employed to produce metal artwork, decorative pieces, and sculptures involving intricate bends and shapes.

Foodservice and Hospitality: Finger Brakes can be used to manufacture food containers, cookware, and serving trays, catering to the needs of the foodservice and hospitality industry.

Medical Equipment Parts: In the medical field, Finger Brakes are applied for manufacturing medical equipment components like brackets, racks, and casings.

Coolers and Radiators: Finger Brakes play a role in producing fins and casings for coolers and radiators, enhancing heat dissipation efficiency.

Laboratory Equipment: Finger Brakes are utilized in manufacturing supports, trays, and sample containers for laboratory equipment.

Art and Creative Projects: Finger Brakes are valuable tools for creative art projects, enabling the creation of unique shapes and structures.

Bending Complexity:

Press Brake: Press Brakes are suitable for precision bending of larger and thicker sheets. They are used for projects requiring consistent bends along a single axis.

Finger Brake: Finger Brakes excel at creating complex box-like shapes, pans, and trays with multiple bends and flanges. They are ideal for projects involving intricate shapes and custom designs.

Bending Precision:

Press Brake: Press Brakes, especially those equipped with CNC technology, offer high precision in terms of angle, depth, and length of bends.

Finger Brake: Finger Brakes provide good precision, particularly in shaping and bending custom forms with adjustable fingers.

Setup Flexibility:

Press Brake: Press Brakes may require tooling changes for different bending angles and shapes, which can take time.

Finger Brake: Finger Brakes have adjustable fingers that can be positioned quickly, allowing for rapid changes between different bending operations.

Material Thickness:

Press Brake: Press Brakes are better suited for bending thicker materials due to their hydraulic or mechanical power.

Finger Brake: Finger Brakes are designed for thinner materials, making them ideal for projects that involve lightweight sheet metal.

Batch Production:

Press Brake: Press Brakes are well-suited for batch production of consistent parts that require the same bending specifications.

Finger Brake: Finger Brakes are useful for creating varied shapes and sizes in smaller quantities or one-off designs.

Automation and CNC:

Press Brake: Many Press Brakes are equipped with CNC controls, allowing for automated and precise bending sequences.

Finger Brake: While some Finger Brakes can have manual CNC-like controls, they are generally more manually operated.

Versatility:

Press Brake: Press Brakes can handle a wide range of bending tasks but are optimized for straightforward bends.

Finger Brake: Finger Brakes are versatile in creating complex shapes, especially those with multiple bends and flanges.

Tooling and Cost:

Press Brake: Press Brakes may require more specialized tooling for different bending needs, which can impact costs.

Finger Brake: Finger Brakes have adjustable fingers that minimize the need for additional tooling, potentially reducing costs.

Project Requirements: Firstly, clarify the requirements of your project. What bending angles, shapes, and sizes are needed? If your project involves intricate multiple bends and flanges, a Finger Brake might be more suitable.

Material Thickness: Consider the thickness of the metal sheets you'll be working with. Press Brakes are suitable for thicker materials, while Finger Brakes are designed for thinner ones.

Batch Production: If you need to mass-produce parts with the same specifications, a Press Brake might be more fitting as it can provide consistent bending.

Complexity: If your project demands complex custom shapes or multiple bends, the adjustability of a Finger Brake might be advantageous.

Automation Requirements: If you require automated precision bending sequences, Press Brakes often come equipped with CNC controls and automation features.

Space and Budget: Factor in your workspace and budget. Press Brakes typically require more space, while Finger Brakes are often more compact and cost-effective.

Skill Level: Consider the skill level of your operators. The automation of a Press Brake might entail higher training costs, while a Finger Brake is generally more user-friendly.

Project Diversity: If you frequently deal with parts of varying shapes and sizes, the adjustability of a Finger Brake might be more suitable.

Future Needs: Consider your future project requirements. Opt for equipment that can cater to evolving and diverse demands.

In the dynamic landscape of metalworking, the choice between a Press Brake and a Finger Brake becomes pivotal, akin to selecting the right brushstroke for a masterpiece. Each of these bending techniques offers its own palette of advantages, allowing manufacturers to craft their designs with finesse and precision. If you have any questions about sheet metal bending, please feel free to contact Durmark!

.png)