Request a Quote

Request a Quote

Table of contents:

3.Advantages and features of Press Brake

Working principle and operation process

Applicable materials and plate thickness range

The bending angle and precision of the bending machine

Suitable for processing complex shapes

4.Advantages and Features of Punch Press

Working principle and operation process

Applicable materials and plate thickness range

Punching type and precision of punching press

Suitable for continuous mass production

5.Considerations for choosing Press Brake or Punch Press

Product Type and Processing Requirements

Production scale and production efficiency

Equipment investment and maintenance costs

Operation skills and training requirements

Small batch customized products

In the sheet metal processing industry, Press Brake and Punch Press are two common processing equipment that play an important role in sheet metal processing. When faced with the choice of Press Brake or Punch Press, multiple factors need to be considered comprehensively to meet product processing requirements and improve production efficiency and economic benefits. They will be introduced in detail below.

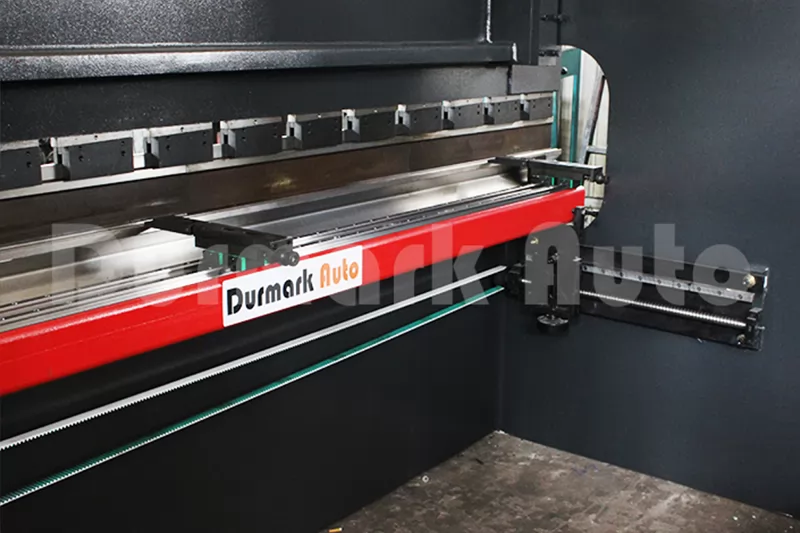

Press Brake is a type of mechanical equipment widely used in sheet metal processing. Its main function is to bend metal sheets into desired shapes and angles. A bending machine usually consists of a driving device, a slide, a table, a punch and a die.

punch and a die.

During operation, the drive unit drives the slide to apply downward pressure, causing the punch and die to bend the sheet metal. Bending in different shapes and angles can be achieved by adjusting the position and shape of the punch and die.

Bending machines are suitable for a variety of different types of sheet metal, including steel, stainless steel, aluminum, and more. It is widely used in sheet metal processing, manufacturing, construction and other fields to produce various metal components, parts and products.

The type and performance of press brakes vary by manufacturer and specification, with mechanical, hydraulic, pneumatic, and servo-electric types to choose from. According to processing needs and budget, choosing a suitable bending machine is very important to improve production efficiency and product quality.

The Punch Press is mainly used for punching and cutting operations on sheet metal. A punch press usually consists of a main frame, a slider, a mold and a control system. The CNC punching machine precisely controls the movement and punching position of the punching machine through the computer control system, which can realize efficient and accurate punching processing.

During operation, the punching machine applies high-speed impact force to the metal plate through the punch on the die, thereby forming the desired hole or cut shape in the metal plate. The mold of the punching machine can be customized according to the needs to meet the punching or cutting requirements of different sizes and shapes.

Punching machines are widely used in industrial manufacturing, auto parts, electronic equipment and other fields. Its impact speed and punch tonnage can be adjusted according to needs, suitable for small batch customized production and large-scale continuous production.

Working principle and operation process

working principle:

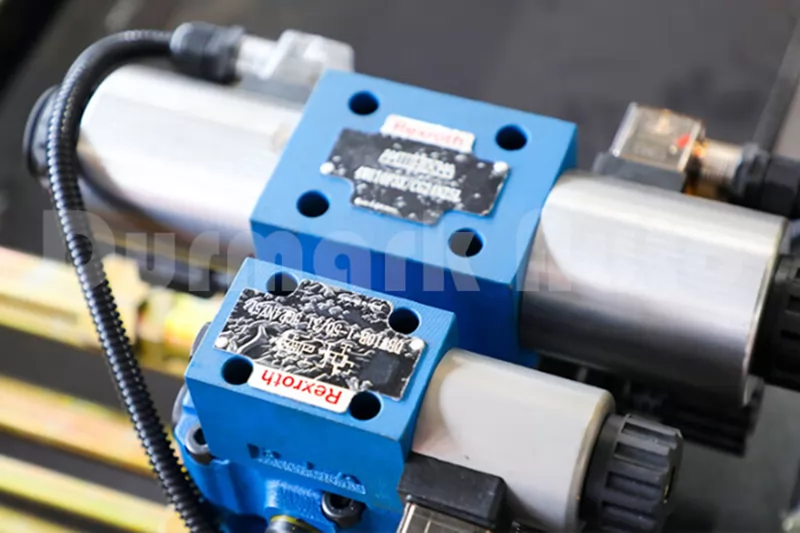

Driving device: The working principle of the Press Brake is powered by the driving device, usually hydraulic or servo motor, which is used to drive the slider (also known as the upper die) to apply pressure downward.

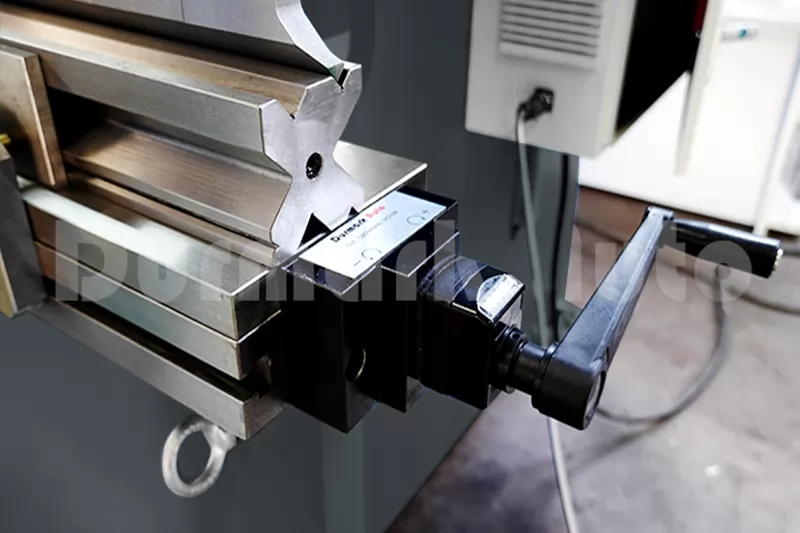

Dies and punches: A set of dies and punches are set on the workbench. The punch is part of the upper die, and the die is part of the table. Bending in different shapes and angles can be achieved by adjusting the position and shape of the punch and die.

Operating procedures:

Preparation: Place the metal plate to be processed on the workbench of the bending machine, and select the appropriate mold and punch according to the processing requirements.

Adjust the position: adjust the distance between the slider (upper die) and the worktable (lower die) as needed to suit the thickness of the metal plate and the desired bending angle.

Position the metal plate: accurately position the metal plate on the workbench to ensure the accuracy and stability of processing.

Operation control: Start the driving device, control the descending speed and pressure of the slider through the operation control system, and make the punch and die bend the metal plate.

Complete bending: After the slide block descends to apply pressure, the metal plate will complete the required bending process under the action of the die and punch.

Inspection and adjustment: After the bending is completed, check whether the quality and size of the workpiece meet the requirements, and adjust and reprocess if necessary.

Workpiece removal: The finished metal plate is removed from the workbench, ready for the next process or delivery.

Applicable materials and plate thickness range

Applicable materials:

Cold-rolled steel plate: Cold-rolled steel is one of the most common metal materials and is widely used on bending machines. It has good strength and plasticity, suitable for most applications.

Stainless steel plate: Stainless steel has corrosion resistance and high temperature resistance, and is suitable for the manufacture of products that require anti-corrosion and aesthetics.

Aluminum alloy plate: Aluminum alloy is lightweight and corrosion-resistant, and is widely used in aerospace, automobile manufacturing and other fields.

Copper and Brass Plates: Copper and brass have good electrical and thermal conductivity and are suitable for applications such as electrical and heat exchangers.

Spring steel plate: Spring steel has excellent elasticity and resilience properties, and is widely used in the manufacture of springs and other parts.

Plate thickness range:

The Press Brake can handle metal plates of different thicknesses, the range of plate thickness depends on the tonnage and performance of the Press Brake. Generally speaking, the plate thickness range of Press Brake is usually between a few millimeters and tens of millimeters, and the details are as follows:

Small Press Brake: Suitable for thinner metal plates, the plate thickness range is usually between 0.5mm and 6mm.

Medium Press Brake: suitable for medium thickness metal plate, the plate thickness usually ranges between 6mm and 12mm.

Large Press Brake: It is suitable for thicker metal plates, and the plate thickness range is usually above 12mm.

The bending angle and precision of the bending machine

Bend angle:

Bending angle range: Bending machines can usually achieve bending angles from a few degrees to 180 degrees. The specific bending angle range depends on the type and specification of the bending machine, as well as the dies and punches used.

Bending angle adjustment: By adjusting the distance between the slider (upper die) and the worktable (lower die), different bending angles can be achieved. Generally speaking, CNC bending machines are more accurate and convenient when adjusting the bending angle.

Multiple bending: By changing molds and punches of different shapes, the bending machine can realize multiple bending, so as to make complex shapes and angles.

Bending precision:

Bending accuracy index: Bending accuracy is usually used to describe the forming accuracy and deviation of bending parts. It can be expressed as the deviation of the bending angle or the straightness and flatness of the bent parts.

Factors affecting the bending accuracy: The bending accuracy of the bending machine is affected by many factors, including the structure and rigidity of the machine, the accuracy and wear of the mold, the characteristics of the material, and the thickness of the plate.

Advantages of CNC bending machines: Compared with traditional mechanical bending machines, CNC bending machines usually have higher bending accuracy. The CNC system can precisely control the position and pressure of the slider to achieve more precise bending processing.

Suitable for processing complex shapes

The following processing can be performed:

Curved polygons and complex curves

multiple bends

free bending

The precision of CNC bending machine

custom mold

Working principle and operation process

working principle:

Driving device: The working principle of the punching machine is powered by the driving device, usually an electric motor, pneumatic or hydraulic system, which is used to drive the slider (also called the upper die) of the punching machine to reciprocate.

to reciprocate.

Dies and punches: Dies and punches are installed on the punching machine. The punch is located below the slide, and the die is located above the table. Punching and cutting of different shapes and sizes can be achieved by adjusting the shape and size of punches and dies.

Operating procedures:

Preparation: Place the metal plate to be processed on the workbench of the punch press, and select the appropriate die and punch according to the processing requirements.

Secure the Workpiece: Use jigs or other fixtures to keep the sheet metal in a stable position during machining.

Operation control: Start the driving device of the punch press, the slider of the punch press starts to reciprocate, and the punch quickly impacts the metal plate.

Complete punching or cutting: The impact of the punch creates the desired hole or cut shape in the sheet metal. After finishing punching or cutting, the slider returns to its original position.

Inspection and adjustment: After finishing processing, check whether the quality and size of the workpiece meet the requirements, and adjust and reprocess if necessary.

Workpiece removal: The finished sheet metal is removed from the press, ready for the next process or delivery.

Applicable materials and plate thickness range

Applicable materials:

Cold-rolled steel plate: Cold-rolled steel is one of the most common punching materials, with good strength and plasticity, suitable for various general punching and cutting operations.

Stainless steel plate: Stainless steel has corrosion resistance and high temperature performance, and is suitable for the manufacture of products and parts that require corrosion resistance.

Aluminum alloy plate: Aluminum alloy has light weight and corrosion resistance, and is widely used in aerospace, automobile manufacturing and other fields.

Copper plate and brass plate: Copper and brass have excellent electrical and thermal conductivity, and are suitable for processing products that require electrical conductivity.

Spring steel plate: Spring steel has excellent elasticity and resilience properties and is used to make springs and other parts.

Plate thickness range:

Punch presses can handle sheet metal of different thicknesses, the range of sheet thickness usually depending on the type and specification of the punch press, as well as the dies and punches used. Generally speaking, the plate thickness range of the punch press is usually in the following range:

Small punch press: suitable for thinner metal plates, the plate thickness range is usually between 0.1mm and 3mm.

Medium Punch Press: Suitable for medium thickness sheet metal, usually ranging from 3 mm to 6 mm in thickness.

Large punch: suitable for thicker metal plates, the plate thickness range is usually above 6mm.

Punching type and precision of punching press

A punch press is a mechanical device used for metal processing. Common punching types include round, square, oval, and multi-hole. The punch press can also make punches of special shapes. Punching accuracy is an important index to describe the size and position accuracy of punched parts, which is affected by factors such as punch, die, punch structure and metal sheet. The CNC punching machine achieves higher punching precision through computer control, and is suitable for punching processing that requires high precision. Reasonable selection of the type of punching machine and attention to the control of punching precision can ensure product quality and processing efficiency.

Suitable for continuous mass production

The punch press is suitable for continuous mass production, and its high-speed impact, automatic operation and stability advantages make it perform well in the industrial field. Equipped with dies and punches, the punching machine can achieve fast and efficient punching and cutting operations. CNC punching machines are capable of high precision and complex processing in mass production. Punching machines are used in a wide range of applications, including automobile manufacturing, electronics manufacturing and home appliance production. By optimizing the production process, punching machines can achieve high-yield and high-quality continuous mass production and enhance the competitiveness of enterprises.

Product Type and Processing Requirements

product type:

The bending machine is suitable for manufacturing products that need to be bent into specific shapes and angles, such as boxes, shields, angle irons, etc.

Punching machines are suitable for manufacturing products that need to be punched, cut or punched, such as electrical sockets, terminal blocks, gaskets, etc.

Processing needs:

If the product requires complex bending and bending, the bending machine is a more suitable choice, which can achieve multiple bending and angle changes by replacing different molds and punches.

If the product needs to be impacted with multiple holes or large-scale continuous punching production, the punching machine is more suitable. The punching machine can realize various punching types by replacing punches of different shapes.

Production scale and production efficiency

Production scale:

Production scale is an important consideration. If the production scale is small, parts of different shapes need to be produced, and the quantity of each product is small, a bending machine may be more suitable. The bending machine is suitable for manufacturing products that need to be bent and bent, and the mold can be flexibly adjusted to meet the requirements of different products.

If the production scale is large, and a large number of parts of the same or similar shape need to be produced, a punching press may be more suitable. The punching machine has the advantages of high-speed impact and automatic operation, and can continuously produce large quantities of the same product in a short period of time.

Productivity:

Production efficiency is also an important factor in the selection. Punching machines have advantages in continuous mass production, and their high-speed impact and automated operation make them suitable for high-efficiency production tasks. If production requirements require a large number of punching, cutting or punching to be done quickly, a punching machine is a more suitable choice.

The bending machine is suitable for the manufacture of products that require complex bending and bending. Although the processing speed is relatively slow, it is suitable for situations where the production scale is small and continuous mass production is not required.

Equipment investment and maintenance costs

Equipment investment:

Bending machines and punching machines have different costs in terms of equipment investment. Generally speaking, the initial investment cost of punching machines may be higher, especially for large CNC punching machines, the price is higher. The initial investment cost of a bending machine is relatively low, especially for traditional mechanical bending machines.

It should be noted that the high-speed impact and automation functions of the punch press may enable it to bring higher production efficiency in large-scale continuous production, and may be able to return its higher equipment investment cost in the long run.

Maintenance cost:

Equipment maintenance costs are also an important consideration. Punching machines usually consist of more moving parts and require more frequent maintenance and maintenance to ensure the stable operation of the equipment. The bending machine is usually relatively simple, and the maintenance cost is relatively low.

The maintenance and repair of CNC equipment usually requires professional technical support, which will also increase maintenance costs. For the bending machine, some maintenance work can be done by the operator himself, reducing maintenance costs.

Operation skills and training requirements

Operating skills:

The operation of the bending machine is relatively simple. Generally, the operator is required to master basic mechanical operation skills, measurement and adjustment skills, and understand the safe operation procedures of the bending machine.

The operation of the punch press is relatively complicated and requires the operator to have more technical skills. The operator needs to master the control system and programming skills of the punch press, understand the use of different punches and dies, and be familiar with automatic operation and equipment maintenance knowledge.

Training requirements:

For bending machines, training is usually relatively simple, and general operation training can be completed in a short time. Some manufacturers also provide training courses for specific models of bending machines to help operators better use the equipment.

For punch presses, the training requirements are relatively higher. The operation of the CNC punching machine requires the operator to have certain computer skills and programming skills. Therefore, training usually requires longer time and professional guidance.

Small batch customized products

Bending machine scheme:

According to the requirements of different products, the bending machine can use molds of different shapes and sizes for bending and bending operations to meet the requirements of small batch customization.

For complex bending requirements, the bending machine can achieve multiple bending and angle changes by replacing different molds, with high flexibility.

Compared with large-scale continuous production, the small-batch customized production is relatively simple to operate the bending machine, the operator can quickly become familiar with the equipment, and the processing speed is faster.

Due to the small scale of production, the equipment investment and maintenance costs of the bending machine are relatively low, which is suitable for small-scale production.

Punch plan:

The punching machine is suitable for the punching and cutting needs of small batches of customized products, which can quickly realize multi-hole punching operations and improve production efficiency.

For complex punching requirements, the punching machine can use punches of different shapes for customized processing to meet diverse product requirements.

CNC punching machines have advantages in precise control of punching position and size, and are suitable for small batches of customized products that require high precision.

Due to the high initial investment of punching machines, for small-scale production, it is necessary to evaluate the expected return and long-term benefits.

For the case of small-volume customized products, if the product mainly requires complex bending and bending operations, and the production scale is small, the bending machine may be more suitable; if the product mainly requires complex punching and cutting operations, and requires high precision, The punching scheme can be considered.

Bending machine scheme:

For parts with simple shapes, the bending and bending functions of the bending machine may not be the optimal choice, because the shape of the part does not require complex bending operations.

The operation of the bending machine is relatively simple, but in mass production, due to the need to change molds frequently, it may lead to a decrease in production efficiency.

Given the large scale of production, operator training and proficiency on the press brake can take time.

Punch plan:

For the production of a large number of parts, the high-speed impact and automatic operation of the punching machine have obvious advantages. The punching machine can realize continuous and efficient punching and cutting operations and improve production efficiency.

For parts with simple shapes, the punching function of the punching machine is very suitable, and it can quickly complete large-scale punching tasks.

The CNC punching machine has a high-precision control system, which can ensure the consistency and stability of the part size.

For mass production of parts with simple shapes and large quantities, the punch solution may be more suitable. The high-speed impact and automatic operation of the punching machine can improve production efficiency and ensure that the needs of mass production are met. At the same time, the precise control capability of the CNC punching machine can also ensure the accuracy and stability of the part size.

First of all, it is necessary to clarify the type of product to be processed and the processing requirements. Bending machines are suitable for products that need to be bent and bent, while punching machines are suitable for operations such as punching, cutting and punching. According to the shape and processing requirements of the product, select the appropriate processing equipment.

as punching, cutting and punching. According to the shape and processing requirements of the product, select the appropriate processing equipment.

Consider production scale and expected production efficiencies. If large-scale continuous production is required, punching machines usually have the advantages of high-speed impact and automatic operation, which can improve production efficiency. If it is a small batch of customization or frequent product changes, a bending machine may be more suitable.

Consider the type of material and range of plate thicknesses to be machined. Bending machines are generally suitable for thicker sheet metal, while punch presses are for thinner sheet metal. Make sure that the selected equipment can meet the requirements of the processing material.

Evaluate the investment and maintenance costs of equipment. The initial investment of a punching machine may be high, but it is highly efficient in large-scale serial production. The initial investment of the bending machine is relatively low, which is suitable for small-scale production. At the same time, the brand, performance and maintenance cost of the equipment must also be considered.

Consider operator skill level and training requirements. The operation of the bending machine is relatively simple and the training is easy; the operation of the punching machine may be more complicated and requires more technical support and training.

For products that require high-precision processing, such as auto parts or electronic parts, CNC equipment is usually more suitable. At this time, you can choose a CNC bending machine or a CNC punching machine.

Making choices according to your production needs and budget will help increase production efficiency and achieve better processing quality. If your production process involves parts with complex bending and different shapes, you may need to have both press brake and Punch Press to meet different processing needs.Feel free to contact Durmark if needed.

.png)