Request a Quote

Request a Quote

With the development of industrial technology, industrial press brakes machines are booming, and a large number of press brakes manufacturers have appeared in the world. Most buyers want to know which industrial bending machine manufacturers are better, but few people choose to buy the best press brakes machine. The reason is simple:very expensive!

Therefore, we have listed some of the industrial press brakes machine manufacturers that are more popular with customers. Their cnc press brakes machines are cheap and fully functional, which are very suitable for purchase and use! Friends who have purchase needs can take a look.

The utilization of press brakes, industrial machinery that facilitates the bending and shaping of sheet metal, is extensive across several industries, such as the automotive, aerospace, construction, and electrical sectors. The press brakes market has been growing consistently over the years, driven by the mounting demand for bespoke sheet metal items, mainly in the emerging economies.

This market is divided into subcategories based on the mode of operation, type, and end-use industry. The type category encompasses hydraulic press brakes, mechanical press brakes, and pneumatic press brakes, with the hydraulic press brakes leading the market because of their ability to deliver high precision and power. The mode of operation is segmented into manual, semi-automatic, and automatic press brakes, with the automatic section set to record the most significant growth, given the increasing need for automation in the manufacturing sector.

Furthermore, based on the end-use industry, the market is segmented into the automotive, aerospace, construction, electrical, and other industries. The automotive industry holds the highest share, owing to the escalating demand for fuel-efficient and lightweight vehicles. The aerospace industry is also expected to experience notable growth as a result of the mounting demand for lightweight and long-lasting components.

Geographically, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. The Asia-Pacific region dominates the market, fueled by the rising demand for press brakes in the manufacturing sector of countries such as China and India. The region is expected to experience notable growth, with increasing investments in the automotive and aerospace industries.

| Company | Logo | Established | Country | Details |

|---|---|---|---|---|

| Accurpress |

|

1973 | Canada | Learn More |

| Aliko |

|

1978 | Finland | Learn More |

| Amada |

|

1937 | Japan | Learn More |

| Bystronic |

|

1964 | Switzerland | Learn More |

| Cincinnati |

|

1890 | United States | Learn More |

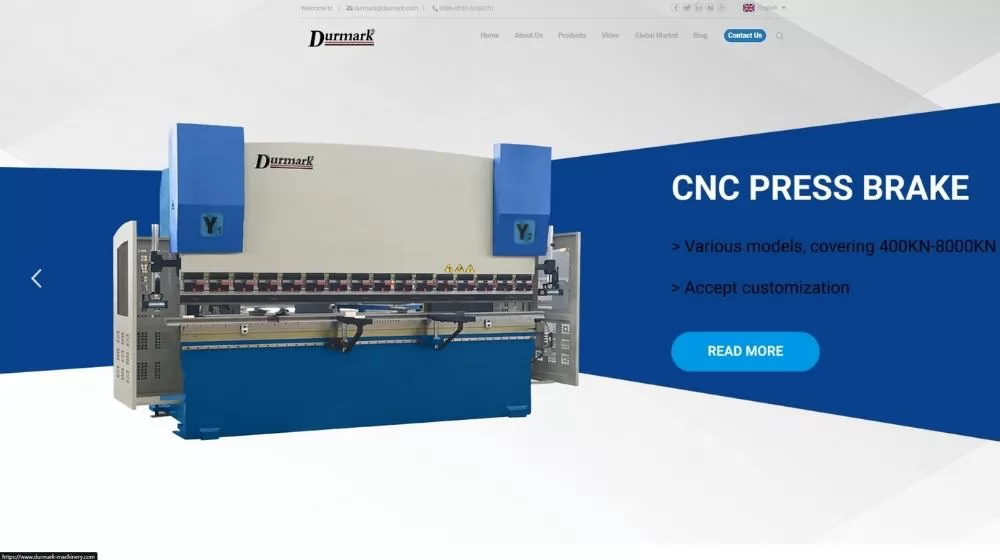

| Durmark |

|

2010 | China | Learn More |

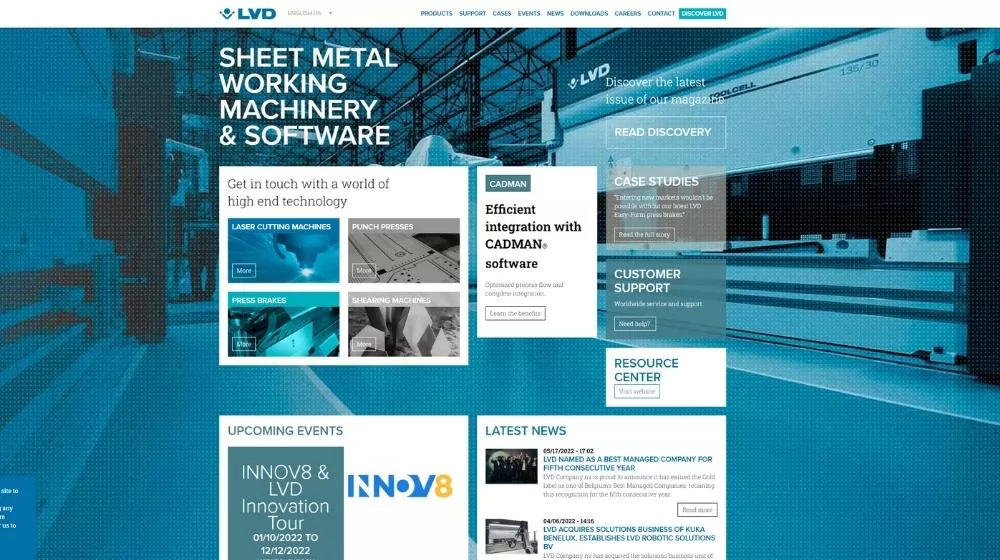

| LVD |

|

1870 | UK, USA | Learn More |

| Prima Power |

|

1977 | Italy | Learn More |

| Salvagnini |

|

1963 | Italy | Learn More |

| Trumpf |

|

1923 | Germany | Learn More |

In order to help buyers better find outstanding manufacturers of bending machines, we have listed the top 10 manufacturers in 2025. For your reference!

Country: Canada

Introduction

Accurpress, the leading press brake manufacturer with over 45 years in the market, continues to build on its proven history of manufacturing an innovative and complete range of press brakes and shears for a variety of bending and shearing applications .

Proud of North American manufacturing, Accurpress leads the way with high tonnage machines, revolutionary bar bending technology, tandem machines and robotic automation. Accurpress has sold over 21,000 machines to thousands of satisfied customers and continues to manufacture bending machines and shears to meet the needs of the manufacturing environment.

Establishment Date:1978

Country:Finland

Introduction

ALIKO has been in the mechanical engineering industry since 1978, manufactures CNC press brake and is a leading press brake manufacturer. According to the company's public information, it has delivered more than 1,300 machines to countries such as Finland. ALIKO's strength lies in the development of new products, which are widely praised for their design and flexibility. The machinery he produces brings high quality while being expensive. Machinery produced many years ago is still on the production line.

Today, in order to adapt to the changing needs of the sheet metal processing industry, the company focuses on its core skills: product development, design and life-long care services for sheet metal machinery.

Establishment Date:1937

Country:Japan

Introduction

Founded in 1937, the company is a well-known press brake manufacturer in Japan. They produce many types of sheet metal machines and are especially known for the precision of their machines and the variety of models. It can provide a wide range of products dedicated to cutting, bending or punching processes, such as bending machines, laser machines, punch/laser combination machines.

Establishment Date:1964

Country:Switzerland

Introduction

Bystronic is a leading global provider of high-quality solutions for the sheet metal processing business. The focus lies on the automation of the complete material and data flow of the cutting and bending process chain. Bystronic’s portfolio includes laser cutting systems, press brakes, and associated automation and software solutions. Comprehensive services round off the portfolio.

Establishment Date:1890

Country:United States

Introduction

Cincinnati is one of the few press brake manufacturers in the United States that produce to order, and has delivered more than 50,000 machine tools in more than 100 years of operation. They can provide laser cutting systems, automation, bending machines, shears, powder Industrial equipment such as metal presses.

Establishment Date:2010

Country:China

Introduction

Anhui Lifu Machinery Technology Co., Ltd. is a company integrating design, development, production and sales. The main development direction is to produce various CNC machines to realize machine automation. Focus on technology research and development, with a complete research and development team, a total of 16 senior engineers for design, drawing, optimization and other work. The company's main products: Shearing Machine, Press Brake, Hydraulic Press Machine, Power Press, Hydraulic Ironworker, Rolling machine, Production Line.

Establishment Date:1952

Country:Belgium

Introduction

Founded in the 1950s, LVD is a manufacturer of precision press brake and is recognized. Significant growth in the 1990s included the acquisition in 1998 of Strippit, Inc., an American manufacturer of turret press equipment, and the addition of laser cutting products to its product portfolio, which made the company a laser, stamping and folding Bend leader technology.

Country:Italy

Introduction

Prima Power is a leading expert in sheet metal processing machines and systems. Their products in this field are one of the most extensive, covering all applications: laser processing, stamping, shearing, bending, automation.

Their manufacturing plants are located in Italy, Finland, the United States and China, and they provide machines and systems worldwide. Their sales and service network has active businesses in more than 80 countries/regions, either directly or through a dedicated dealer network.

Establishment Date:1963

Country:Italy

Introduction

The Salvagnini Group designs, builds and sells flexible systems and machines for processing sheet metal: punching machines, panel benders, press-brakes, fiber laser cutting machines, FMS lines, automatic store-towers and software. Thanks to its global presence, the Group offers direct customer service in 35 countries around the world.

Establishment Date:1923

Country:Germany

Introduction

The TRUMPF Group has 77 subsidiaries and branch offices and more than 13,400 employees generates sales in excess of $ 4.3 billion. The TRUMPF Group is a world leader in sheet metal fabrication machinery and industrial lasers. TRUMPF Inc. is the North American subsidiary of TRUMPF GmbH + Co. KG. based near Stuttgart, Germany. With approximately 870 employees, TRUMPF Inc. is the Headquarters for North America and is one of the largest manufacturers of fabricating machinery in the United States.

When selecting the appropriate press brake for your business, there are various elements to consider. Take into account the following factors prior to finalizing a purchase decision:

Press brakes are available in different sizes and capacities. The capacity of a press brake is determined by the maximum amount of force it can apply to a metal sheet. Ensure that you opt for a press brake that can manage the maximum thickness and size of the metal sheets that you intend to work with.

The bend length of a press brake is the maximum length of the metal sheet it can bend. Consider the length of the metal sheets you'll be working on and choose a press brake with a bend length that can handle it.

The speed of a press brake is determined by how rapidly it can cycle through a bend. Take into account the speed of the press brake and select one that can keep up with your production needs.

The precision of a press brake determines how accurate the bend is. Consider the level of tolerance required for your business and select a press brake that can meet that requirement.

The cost of a press brake is an important factor to consider. Ensure that you opt for a press brake that fits your budget but doesn't compromise on quality.

Choosing the right press brake manufacturer is equally as important as choosing the appropriate press brake. A reputable manufacturer will provide quality products, excellent customer service, and reliable after-sales support. Take into account the following factors when selecting a press brake manufacturer.

Choose a manufacturer with experience in producing press brakes. An experienced manufacturer is more likely to produce high-quality press brakes than a new manufacturer.

Select a manufacturer with a good reputation in the market. Check their online reviews and ask for references from previous customers to ensure that they provide quality products and services.

Choose a manufacturer that offers reliable after-sales support. Ensure that they have a dedicated customer service team that can assist you with any issues you may encounter during the press brake's lifetime.

If you need to buy professional press brake equipment, these manufacturers can choose. If your budget is not particularly sufficient, you can consider choosing an affordable hydraulic press brake machine, such as Durmark.

Read more:

What is CNC Press Brake Machine

What is a shearing machine? Work process and characteristics?

.png)