Request a Quote

Request a Quote

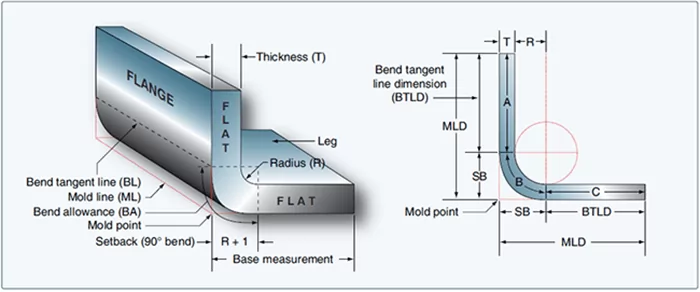

"Sheet metal setback" refers to the distance by which a bend or fold in a piece of sheet metal is set back or positioned from the edge or previous bend. It is a crucial factor in sheet metal fabrication, as the setback determines the accuracy of the final shape and dimensions of the fabricated metal part.

The setback is typically specified in engineering or design drawings to ensure that bends are made at the correct locations to achieve the desired geometry and fit of the sheet metal component.

In the realm of sheet metal fabrication, setbacks are pivotal factors that influence the precision and quality of the bending process. Setbacks can be classified into two main categories: internal setbacks and external setbacks. These setbacks are contingent upon two primary variables: the angle at which the sheet metal is bent and the radius of the bend.

Internal setback, the first category, is a critical measurement that involves determining the distance from the point where the inner radius intersects with the inner formed line to the vertex of that specific inner formed line. This measurement plays a fundamental role in ensuring that the bend is accurately positioned relative to the sheet metal's edge and any preceding bends, ultimately affecting the geometry and fit of the fabricated metal component.

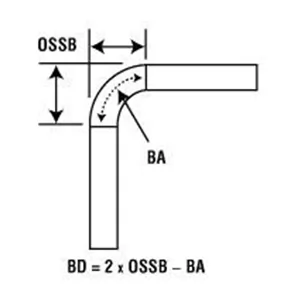

External setback, the second category, is equally significant. It encompasses the measurement of the distance from the point where the radius intersects with the flange to the outer bending vertex. Similar to internal setbacks, external setbacks are influenced by alterations in bending angles and radii. These measurements are indispensable as they enable precise control over the positioning of bends concerning the sheet metal's edges and previous bending operations. By comprehending both external setbacks and the deduction required for bending, engineers and fabricators can calculate the pivotal parameter known as bending allowance, ensuring that the final product conforms to the specified tolerances and requirements.

BA(Bend Allowance)=2OSSB-BD(Bend Deduction)

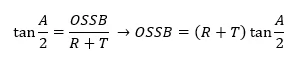

The outside setback can be calculated by the following formula

Outside Setback(OSSB)=Tan(A/2) × (T+R)

The sum of bend deduction and bend allowance is equal to two times the outside setback.

This can be expressed as T (sheet thickness) + A (bend angle) + R (inside bend radius).

For a 90° bend angle, the setback value is equal to the bend radius plus the sheet thickness.

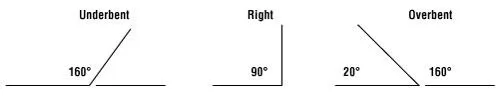

When the bend angle is less than 90°, the complementary angle is usually used, and when the bend angle is greater than 90°, the included angle or complementary angle is usually used.

Understanding the concept of sheet metal setback is essential for achieving precision and accuracy in the field of metal fabrication. By mastering these principles, fabricators and engineers can ensure that their sheet metal components meet the required specifications and tolerances, ultimately leading to high-quality finished products.

At Durmark, we specialize in the production of sheet metal machinery. If you want to know more about sheet metal machinery, please feel free to contact us!

.png)