Request a Quote

Request a Quote

Sheet metal processing technology continues to improve, especially in some applications such as precision stainless steel bending, stainless steel decorative parts bending, aluminum alloy bending, aircraft parts bending, copper plate bending and so on, further put forward higher requirements for the surface quality of the formed workpiece. The traditional bending process is easy to damage the surface of the workpiece, and the surface contacted with the die will form an obvious indentation or scratch, which will affect the aesthetics of the final product and reduce the value judgement of the product by users.

Reasons for Bending Indentation

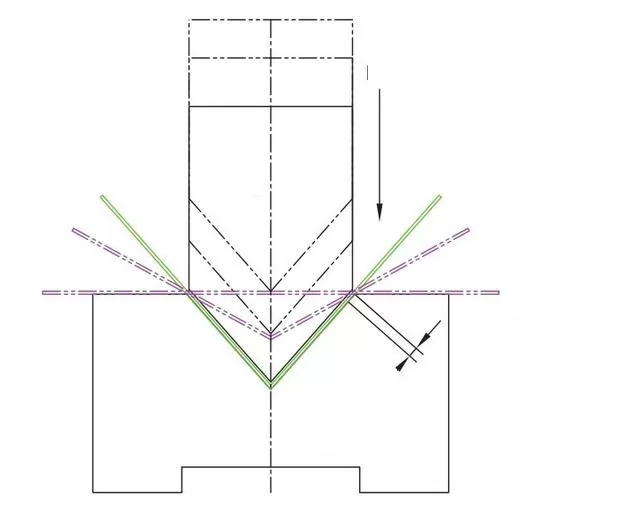

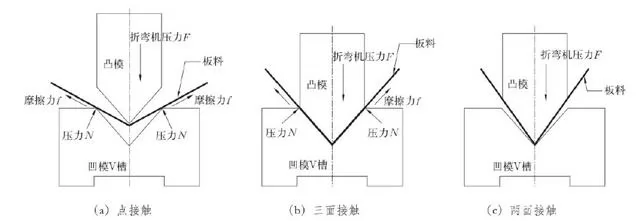

This paper takes bending a V-shaped part as an example to discuss. Sheet metal bending is a process in which sheet metal is first elastically deformed and then plastic deformed under the pressure of punch or die of bending machine. In the initial stage of plastic bending, sheet metal is freely bended. With the pressure of punch or die on the plate, the plate and the inner surface of V-groove of the die gradually close, while the curvature radius and bending force arm gradually become smaller, and continue to press until the end of the stroke, so that the die and the plate close to the full contact of three points, at this time complete a V-bending. When bending, because the sheet metal will be extruded by the bending die to produce elastic deformation, the contact point between the sheet metal and the die will slip along with the bending process. In the bending process, sheet metal will undergo two distinct stages of elastic deformation and plastic deformation. In the bending process, there will be a process of holding pressure (three-point contact between die and sheet metal), so after the bending process is completed, three indentation lines will be formed. These indentation lines are usually produced by the extrusion friction between the sheet and the shoulder of the V groove of the die, so they are called shoulder indentation. As shown in Fig. 1 and Fig. 2, the main causes of shoulder indentation can be simply classified as the following.

Bending method

Since the shoulder indentation is related to the contact between the plate and the V groove shoulder of the die, the gap between the punch and the die affects the compressive stress of the plate during the bending process, and the probability and degree of indentation are also different, as shown in Figure 3. Under the same V-groove condition, the larger the bending angle of the workpiece, the larger the deformation of the sheet metal under tension, and the longer the friction distance between the sheet metal and the shoulder of the V-groove; furthermore, the longer the bending angle is, the longer the holding time of the pressure exerted by the punch on the sheet metal will be, and the more obvious the indentation caused by the combination of these two factors will be.

.png)