Request a Quote

Request a Quote

Laser cutting machine overview

A laser cutting machine is a device that uses laser technology for cutting. It uses a high-energy laser beam to precisely cut the material. Laser cutters can be applied to a variety of materials, including metal, plastic, wood, textiles, and more. Its working principle is to focus the laser beam to a very small point, and achieve the purpose of cutting by heating and evaporating, melting or burning the surface of the material. Laser cutting has the characteristics of non-contact, high precision, high speed and high flexibility, and is widely used in the fields of manufacturing, craft production and design. It plays an important role in improving production efficiency, precisely cutting complex shapes and realizing personalized production.

The history of laser cutting machines can be traced back to the 1960s.

The earliest laser cutting machines mainly used CO2 lasers as the cutting source.

In today's manufacturing industry, it is widely used in automotive, aerospace, electronics, furniture manufacturing, decorative arts and other fields, providing an effective solution for high-precision cutting and processing.

With the continuous development of science and technology, the performance and application fields of laser cutting machines will continue to expand.

There are many different types of laser cutters, the common ones include the following:

Metal laser cutting machine is a kind of laser equipment specially used for cutting metal materials. It uses a high-energy laser beam to heat the metal material to a high temperature, making it melt or evaporate quickly, so as to achieve precise cutting effect.

Fiber laser is usually used as the cutting source, which has the advantages of high energy density, high cutting speed and small heat-affected zone. It can cut various metal materials, including stainless steel, aluminum alloy, carbon steel, etc., and is suitable for metal sheets of different thicknesses.

It is widely used in the manufacturing industry, especially in the fields of automobile, aerospace, electronics, metal processing and so on. It can realize the cutting of complex shapes, has high precision, high efficiency and good cutting quality, and has become an indispensable and important tool in the field of modern metal processing.

High precision laser cutting machine :

High-precision laser cutting machine is a kind of laser equipment with excellent cutting precision. It uses a high-energy laser beam to cut the material to achieve extremely high cutting precision and fine cutting details.

Using advanced optical system and precision control technology, it can achieve micron or even sub-meter cutting accuracy. It is suitable for various materials, including metals, non-metals, organic materials, etc., and is widely used in the fields of electronic device manufacturing, precision machining, and fine parts cutting.

And it has many advantages, such as non-contact cutting, no deformation, narrow kerf, high cutting quality, etc. It can realize the cutting of complex shapes, meet the needs of high-precision processing, and improve production efficiency and product quality.

Whether in the field of industrial manufacturing or in scientific research experiments, high-precision laser cutting machines play an important role. It provides precise and reliable cutting solutions for all walks of life, driving technological progress and innovative development.

Fiber laser cutting machine is a kind of equipment that uses fiber laser for cutting. It uses optical fiber as the laser transmission medium to transmit the laser beam to the cutting head for cutting operation.

It has many advantages. First of all, it has high energy density and high cutting speed, which can cut metal materials quickly and accurately. Secondly, the fiber laser cutting machine adopts optical fiber transmission, which can realize long-distance transmission without losing laser energy, ensuring the stability of cutting quality. In addition, the fiber laser cutting machine has a compact structure and takes up little space, making it suitable for various working environments.

And it is widely used in the field of metal processing. It can deal with different kinds of metal materials, such as stainless steel, aluminum alloy, carbon steel, etc., to achieve high-precision and high-efficiency cutting. Fiber laser cutting machines play an important role in automobile manufacturing, aerospace, electronic device manufacturing and other fields, improving production efficiency and product quality.

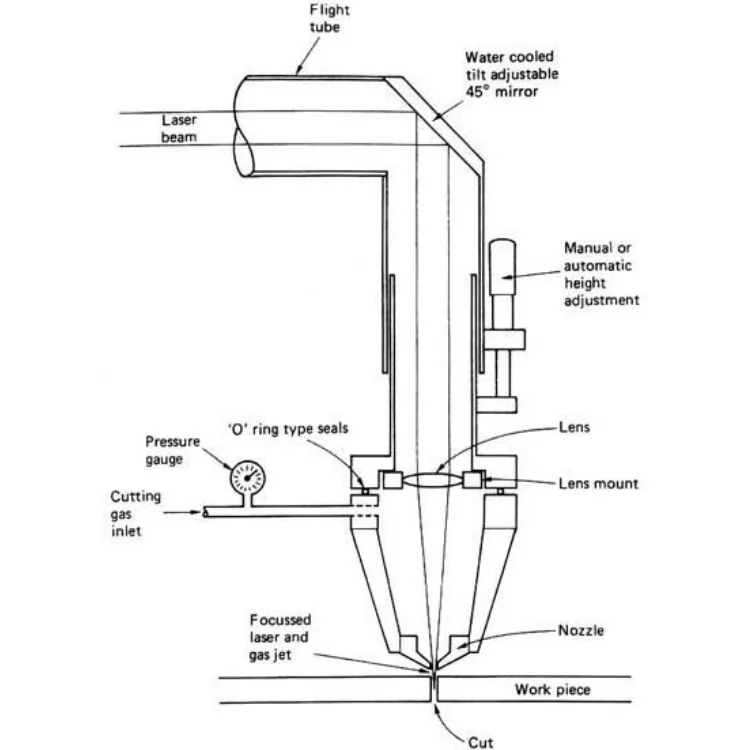

A laser generator produces a high-energy laser beam.

The laser beam is focused by an optical system, making its energy density extremely high.

A high-energy laser beam is shone onto the material to be cut, heating it up.

When the material is heated, part of the area melts or evaporates, forming a cut.

The cutting opening is controlled by the high energy and motion trajectory of the laser beam to achieve precise cutting shapes.

During the cutting process, the motion system of the laser cutting machine can move the workpiece or the laser cutting head to achieve cutting in different shapes and directions.

After the cutting is completed, the laser cutting machine can automatically remove the waste and residue generated by the cutting.

The working principle of laser cutting machines is based on the thermal action of high-energy laser beams, which can cut various materials quickly and precisely. Its advantages include high precision, non-contact cutting, no need for mechanical knives, etc., making it an important tool for a wide range of applications in modern manufacturing.

Power: The higher the laser power, the faster the cutting speed.

Material properties: Different materials have different cutting characteristics, and cutting speed needs to be adjusted for best results.

Cutting quality requirements: When high quality is required, the cutting speed may need to be appropriately reduced to ensure cutting quality.

Cutting parameter setting: reasonable adjustment of cutting parameters such as laser power and gas flow can affect the cutting speed.

Cutting shapes and complexity: Complex shapes and curves may require slower cutting speeds to ensure accuracy.

Laser cutters are suitable for a wide variety of materials, including metals (such as steel, aluminum, copper, etc.), plastics, wood, leather, textiles, plexiglass, and more.

Laser cutting machines have high-precision cutting capabilities, and can usually achieve millimeter-level cutting accuracy, depending on the model and commissioning settings of the laser cutting machine.

Cutting speeds vary depending on factors such as the power of the laser cutter, material type and thickness. Generally speaking, laser cutting machines have a faster cutting speed and can efficiently complete cutting tasks.

What should be paid attention to in the maintenance of laser cutting machine?

The maintenance of the laser cutting machine includes regular cleaning of optical components, inspection and replacement of cutting head parts, keeping the cutting area clean, etc. At the same time, regular maintenance and maintenance according to the manufacturer's instructions is the key to keep the laser cutting machine running normally.

Through the science popularization in this article, I believe you must have some understanding of laser cutting machines.

If you are looking for a suitable laser cutting machine, welcome to contact us!

.png)