Request a Quote

Request a Quote

Are you in pursuit of a multifaceted apparatus that has the potential to heighten your output and precision in the metalworking, automobile, construction, or IT sectors? Search no further than a punch press! Within this guide, we shall expound upon all the requisites you must be knowledgeable of about punch presses, such as their varieties, applications, boons, hindrances, and how to select the appropriate type and manufacturer.

A punch press is a specialized device utilized for forming holes or shapes in a variety of materials, such as metal or plastic. The process involves exerting pressure on the material via a punch press machine, which may be of hydraulic, mechanical, pneumatic, or computer numerical control (CNC) nature. The punch press itself may be composed of a variety of materials, including steel, carbide, or diamond, depending on the application and the nature of the material undergoing processing.

Investing in a punch press can bring numerous benefits to your business, including:

punch presses can perform multiple operations such as punch pressing, forming, bending, and embossing in a single cycle, which saves time and increases efficiency.

punch presses can be equipped with various tools and dies, which allows them to handle a wide range of materials and applications.

punch presses can deliver precise and consistent results, which reduces scrap and waste and improves the quality of the final product.

punch presses can be used in various industries, including:

In the automobile industry, punch presses are used to produce various parts such as chassis, body panels, brackets, and exhaust systems.

In the construction industry, punch presses are used to manufacture structural steel components, including beams, columns, and trusses.

In the IT industry, punch presses are used to produce computer parts, including heat sinks, chassis, and covers.

In the metal processing industry, punch presses are used to produce a wide range of products such as appliances, furniture, machinery, and tools.

In the manufacturing industry, punch presses are used to produce a wide range of products such as cans, closures, and containers.

There are four main types of punch presses, including:

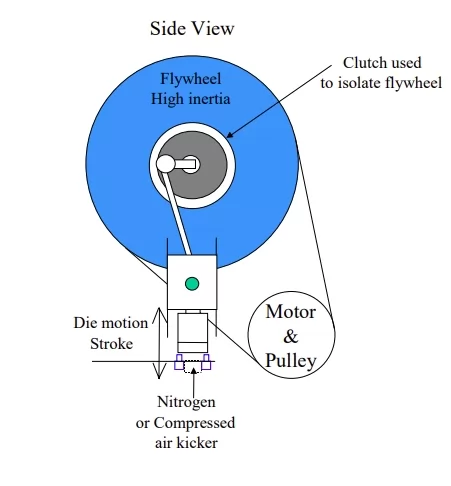

Mechanical punch presses use a flywheel and a crankshaft to deliver force to the punch press. They are suitable for low-volume production and can be operated manually or automatically.

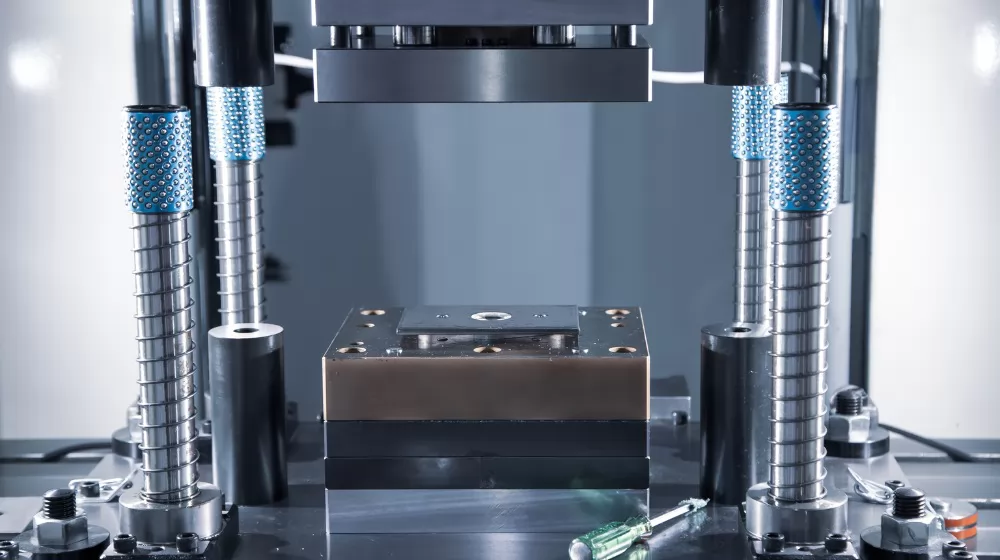

Hydraulic punch presses use hydraulic cylinders to deliver force to the punch press. They are suitable for high-volume production and can be operated manually or automatically.

Pneumatic punch presses use compressed air to deliver force to the punch press. They are suitable for low-volume production and can be operated manually or automatically.

CNC punch presses use computer numerical control (CNC) to control the movement and position of the punch press. They are suitable for high-volume production and can produce complex shapes and contours.

In addition to the benefits mentioned earlier, punch presses have several other advantages, including:

punch presses can deliver accurate and consistent results, which reduces the amount of scrap and waste material.

Punch presses can be equipped with safety features such as guards and interlocks, which protect the operator and prevent accidents.

Punch presses can perform multiple operations in a single cycle, which reduces the processing time and increases efficiency.

As versatile and efficient as punch presses are, there are still limitations to their capabilities. Some of the limitations of punch presses include:

Punch presses are not suitable for producing complex parts with intricate shapes and features.

Purchasing a punch press can be a significant investment, especially for small or medium-sized businesses.

Like any machinery, punch presses require regular maintenance and occasional repairs, which can add to the overall costs of ownership.

Punch presses can be noisy and produce vibrations during operation, which may require additional measures to mitigate.

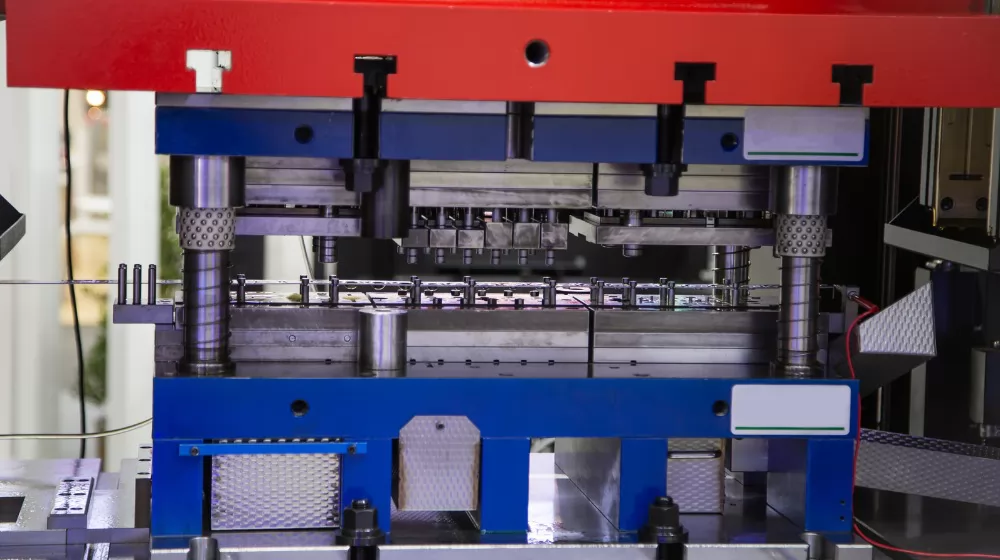

A punch press consists of several key parts, each with its own function and importance. The main parts of a punch press include:

Frame: The main body of the punch press, which houses all other parts.

Clutch: The component that engages and disengages the punch press.

Drive Mechanism: The motor or other device that powers the punch press.

Memory: The device that stores the program or instructions for the punch press operation.

Mold Pad: The component that holds the material being punch pressed.

Support Plate: The plate that provides support for the mold pad and material.

Formwork: The device that holds the punch press in place during operation.

punch press: The tool that actually cuts or shapes the material.

Choosing the right punch press for your punch press is critical to achieving optimal performance and efficiency. When selecting a punch press, consider the following factors:

The punch press must be capable of handling the material and thickness you plan to punch press.

The punch press must be precise and accurate to ensure consistent results.

The punch press should be able to operate at a speed that meets your production needs.

The punch press should be affordable and within your budget.

The punch press should be suitable for the type of punch pressing operation you will be performing.

Choosing the right punch press manufacturer is just as important as choosing the right punch press. When evaluating manufacturers, consider the following factors:

Look for a manufacturer with a long history of producing high-quality punch presses.

Choose a manufacturer that offers a range of punch press types and models to meet your specific needs.

Look for a manufacturer that can customize the punch press to meet your unique requirements.

Choose a manufacturer that offers reliable customer service and support to address any issues that may arise.

Consider the overall value of the punch press, taking into account factors such as quality, features, and support, as well as the price.

After much contemplation, it can be inferred that punch presses are a necessary apparatus that caters to a vast array of industries ranging from construction to manufacturing to automobile. A wise investment in punch presses necessitates understanding the different types of press available, their respective benefits, and limitations, as well as making an informed decision regarding the manufacturer and press chosen.

As far as choosing a manufacturer is concerned, Chinese manufacturers provide unbeatable value and superior quality. They have amassed a substantial following worldwide by producing exceptional quality punch presses at competitive prices for a prolonged period.

Should you seek a reputable and dependable punch press manufacturer in China, it is imperative to conduct thorough research and evaluate the available options critically. Acquiring the right punch press and manufacturer can undoubtedly propel your business towards a more productive and prosperous future.

Read More:

Top 10 Shearing Machine Manufacturer in 2022

How to Choose a Right Shearing Machine Manufacturer

.png)