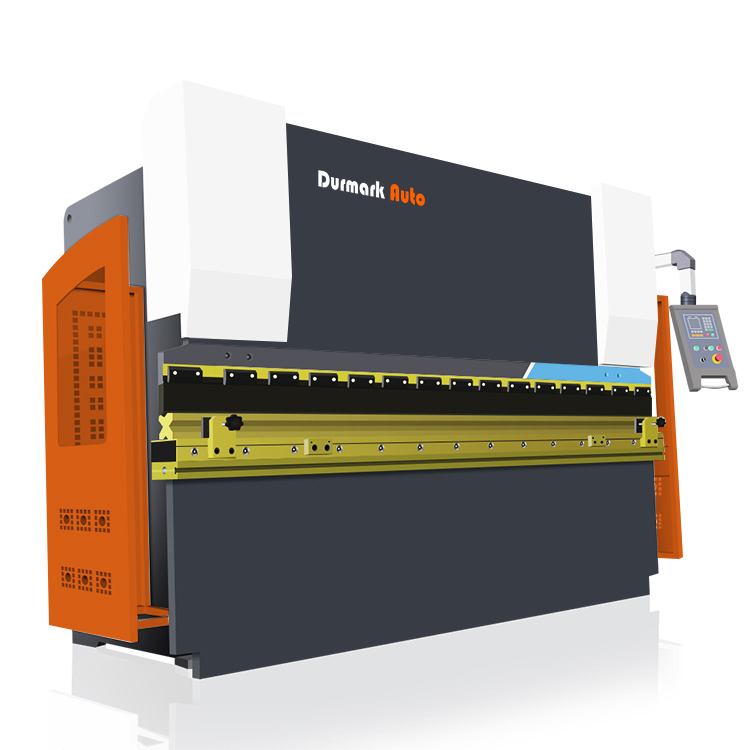

CNC Press Brake for Sale

Welcome to Anhui LIFU Machinery Technology Co., Ltd. (Durmark), your premier destination for high-quality CNC Press Brake machines. With a strong focus on innovation and mechanical automation, we are dedicated to providing you with cutting-edge solutions to meet your manufacturing needs.

As a leading Brushless DC Blower Manufacturer, we specialize in the design, development, production, and sales of a wide range of CNC machines. Our core mission is to deliver superior products that empower you to achieve precision and efficiency in your operations. By harnessing advanced technology and leveraging the expertise of our experienced team, we ensure that our CNC Press Brake machines exceed industry standards.

In addition to our in-house R&D capabilities, we have established long-term partnerships with renowned Metal forming Machinery Research Institutes, as well as leading manufacturers of cutting-edge automation equipment and CNC control systems. These collaborations allow us to stay ahead of the curve and integrate the latest advancements into our products, ensuring optimal performance and reliability.

Spanning across an expansive 100,000 square meters, our state-of-the-art facilities are equipped to handle every aspect of the manufacturing process. From our 2,000 square meter office space to our dedicated workshops for welding, grinding processing, and spare parts warehousing, we have created an efficient and seamless production environment. This commitment to excellence enables us to maintain the highest quality standards throughout the manufacturing process.

Now, experience the power of our CNC Press Brake machines firsthand. Designed with precision and engineered for excellence, our machines deliver exceptional results, whether you're bending sheet metal, forming complex shapes, or executing precise fabrication tasks. Our CNC Press Brake machines offer unmatched accuracy, reliability, and versatility, making them the perfect addition to your manufacturing arsenal.

Don't miss out on this incredible opportunity to enhance your production capabilities. Contact us today to explore our extensive range of CNC Press Brake machines for sale. Whether you're a small-scale workshop or a large-scale industrial facility, we have the perfect solution to meet your unique requirements. Take your manufacturing processes to new heights with Anhui LIFU Machinery Technology Co., Ltd. (Durmark).

In today's modern manufacturing industry, CNC press brakes have become an essential tool for businesses looking to enhance their productivity and efficiency. These machines offer numerous benefits and capabilities that can greatly improve the bending and forming processes. If you're considering investing in a CNC press brake for your business, it's crucial to understand its features, functions, and how to choose the right one. This comprehensive guide will walk you through everything you need to know when buying a CNC press brake for sale.

-

The benefits of investing in a CNC press brake for your business

-

What safety features should I look for in a CNC press brake?

1. Why CNC Press Brakes are Essential in Modern Manufacturing

In the fast-paced world of manufacturing, precision and efficiency are paramount. CNC press brakes play a vital role in meeting these demands by offering precise control over the bending process. With the ability to automate repetitive tasks and execute complex bending sequences, CNC press brakes save time and reduce the margin of error. They enable manufacturers to achieve consistent results, enhance product quality, and meet tight deadlines.

2. The Benefits of Investing in a CNC Press Brake for Your Business

Investing in a CNC press brake can bring numerous benefits to your business. Firstly, it significantly improves productivity by reducing setup and changeover times. With automated tool changes and advanced control systems, you can seamlessly switch between different bending operations, maximizing efficiency.

Secondly, CNC press brakes offer exceptional precision and accuracy. The digital control systems ensure consistent bending angles and eliminate human errors. This leads to higher product quality and reduces the need for rework, saving both time and resources.

Thirdly, CNC press brakes enhance flexibility and versatility in manufacturing. They can handle a wide range of materials and thicknesses, allowing you to expand your product offerings. Additionally, these machines enable complex bending sequences and can create intricate shapes, opening up new design possibilities.

3. What is a CNC Press Brake?

A CNC press brake is a machine used for bending and forming sheet metal or plate material. It consists of a hydraulic or electric system that applies force to a punch, which presses the material against a die, bending it to the desired angle. The CNC (Computer Numerical Control) aspect refers to the sophisticated control system that automates the bending process, eliminating the need for manual adjustments.

4. How Does a CNC Press Brake Work?

The working principle of a CNC press brake involves several key components. First, the material to be bent is positioned between the punch and die. The CNC control system then activates the hydraulic or electric system, applying force to the punch, which gradually bends the material. The control system precisely regulates the bending process, monitoring the position, force, and angle to achieve accurate results.

5. Key Components of a CNC Press Brake

A CNC press brake comprises various components that work together to execute the bending process. These include:

Frame: The frame provides structural stability and houses the main components of the press brake.

Punch and Die: The punch is the upper tool that applies force to the material, while the die is the lower tool that provides the bending shape.

Hydraulic or Electric System: This system generates the force required to bend the material. Hydraulic systems use hydraulic cylinders, while electric systems employ servo motors.

Backgauge: The backgauge consists of movable fingers that position the material accurately for precise bending.

Control System: The control system, operated through a user-friendly interface, allows you to program and automate the bending process.

Safety Features: CNC press brakes are equipped with safety measures such as light curtains, emergency stops, and safety interlocks to protect operators from accidents.

6. Types of CNC Press Brakes

There are different types of CNC press brakes available, each suited for specific applications and production requirements. The 3 main types of CNC press brakes are:

Hydraulic CNC Press Brakes

Hydraulic CNC press brakes are known for their power and versatility. They utilize hydraulic systems to generate force, providing high bending capacities. These press brakes are ideal for heavy-duty applications and materials with larger thicknesses. Hydraulic press brakes offer precise control and can execute complex bending sequences with ease.

Electric CNC Press Brakes

Electric CNC press brakes are gaining popularity due to their energy efficiency and accuracy. They employ servo motors instead of hydraulic systems, resulting in lower power consumption and reduced maintenance requirements. Electric press brakes offer fast and precise bending, making them suitable for applications that demand high precision and small part production.

Hybrid CNC Press Brakes

Hybrid CNC press brakes combine the benefits of both hydraulic and electric systems. They utilize hydraulic power for major bending operations and employ electric servo motors for finer adjustments and positioning. This hybrid approach offers a balance between power and energy efficiency, making them versatile and suitable for various applications.

7.Factors to Consider When Buying a CNC Press Brake

When purchasing a CNC press brake, several factors should be taken into consideration to ensure you choose the right machine for your needs. These factors include:

Working Capacity and Bending Force Requirements

Evaluate the maximum bending force and working capacity needed for your specific applications. Consider the material types, thicknesses, and the maximum length of the parts you'll be bending.

Machine Size and Footprint

Assess the available space in your manufacturing facility and determine the appropriate size of the press brake. Consider not only the machine's dimensions but also the required clearance around it for operation and maintenance.

Backgauge and Control System Features

The backgauge plays a crucial role in positioning the material accurately for bending. Look for a CNC press brake with a precise and reliable backgauge system. Additionally, consider the features and capabilities of the control system, such as programming options, user interface, and automation capabilities.

Tooling Options and Compatibility

Check the availability and compatibility of tooling options for the press brake. Different tooling options allow for various bending operations and shapes. Ensure that the press brake you choose can accommodate the tooling required for your specific applications.

Safety Features and Certifications

Safety should be a top priority when selecting a CNC press brake. Look for machines that come with safety features such as light curtains, emergency stops, and safety interlocks. Additionally, ensure that the press brake complies with relevant safety certifications and standards.

Budget Considerations

Define your budget range and explore options that offer the best value for your investment. Consider not only the initial purchase price but also the long-term costs associated with maintenance, service, and tooling.

8. What is the Average Cost of a CNC Press Brake?

The cost of a CNC press brake can vary depending on several factors, including the machine's size, capabilities, brand reputation, and additional features. Generally, CNC press brakes range in price from $50,000 to $500,000 or more. It's essential to carefully evaluate your requirements and budget constraints to make an informed decision.

9. How to Choose a CNC Press Brake Manufacturer

Selecting a reputable and reliable CNC press brake manufacturer is crucial to ensure the quality and performance of the machine. Consider the following steps when choosing a manufacturer:

Identifying Reputable Suppliers

Research and identify well-established manufacturers with a proven track record in producing high-quality CNC press brakes.

Evaluating Supplier Experience and Expertise

Assess the manufacturer's experience in the industry and their expertise in producing CNC press brakes. Look for manufacturers with a solid reputation and positive customer feedback.

Reading Customer Reviews and Testimonials

Check online reviews and testimonials from customers who have purchased CNC press brakes from the manufacturer you're considering. This will provide insight into their customer satisfaction and the overall quality of their machines.

Requesting Quotes and Comparing Pricing

Contact multiple manufacturers and request quotes for the CNC press brake models that meet your requirements. Compare the pricing and consider the value you'll receive for your investment, including the machine's features, warranty, and after-sales support.

10. Assessing Machine Quality and Performance

To ensure you choose a CNC press brake that meets your expectations, it's important to assess its quality and performance. Consider the following factors:

Material and Build Quality

Examine the construction and materials used in the press brake's frame, components, and tooling. High-quality materials and robust construction contribute to the machine's durability and longevity.

Precision and Accuracy

Look for CNC press brakes that offer high precision and accuracy in bending. Pay attention to the control system's capabilities and the machine's repeatability.

Speed and Productivity

Consider the press brake's bending speed and its impact on your production requirements. Faster bending speeds can enhance productivity and throughput.

Ease of Maintenance and Service

Evaluate the ease of maintenance and the availability of service and support from the manufacturer. A reliable support network ensures minimal downtime and timely assistance when needed.

11. Can a CNC Press Brake Handle Different Materials?

Yes, CNC press brakes can handle a wide range of materials, including mild steel, stainless steel, aluminum, and various alloys. However, the machine's bending capacity and tooling options may vary depending on the material's thickness and properties. It's essential to choose a press brake with the appropriate capacity and tooling to handle the materials you work with.

12. What Safety Features Should I Look for in a CNC Press Brake?

Safety is of utmost importance when operating a CNC press brake. Look for machines that offer the following safety features:

Light curtains: These sensors detect the presence of an operator's hand or body near the bending area and automatically stop the machine to prevent accidents.

Emergency stops: Easily accessible emergency stop buttons that can immediately halt the machine's operation in case of an emergency.

Safety interlocks: Mechanisms that prevent the machine from operating when safety doors or guards are open, ensuring the operator's safety.

These safety features help protect operators from potential hazards and create a safe working environment.

By considering the factors mentioned in this guide and selecting a reputable CNC press brake manufacturer, you can confidently make an informed decision when buying a CNC press brake for your business. Invest in a high-quality machine that aligns with your production requirements and positions your business for success in the world of modern manufacturing.

Choosing the Best CNC Press Brake Manufacturer in China

In conclusion, investing in a CNC press brake can revolutionize your manufacturing processes, enhancing productivity, precision, and versatility. As you embark on the journey of purchasing a CNC press brake, it is essential to carefully consider your specific requirements, evaluate reputable manufacturers, and prioritize machine quality and performance.

At Durmark, we take pride in being a trusted name in the press brake industry. With years of experience and expertise, we offer a wide range of high-quality CNC press brakes that cater to diverse manufacturing needs. Our machines are built to deliver exceptional precision, durability, and efficiency, ensuring that your production processes run seamlessly.

By choosing Durmark as your CNC press brake manufacturer, you gain access to cutting-edge technology, robust construction, and comprehensive customer support. We prioritize your success and satisfaction, and our team is dedicated to providing prompt assistance, maintenance services, and reliable spare parts.

Don't miss out on the opportunity to elevate your manufacturing capabilities with a Durmark CNC press brake. Take the first step towards transforming your business by sending us an inquiry today. Our expert team is ready to provide you with a personalized quote and guide you through the process of finding the perfect CNC press brake that meets your unique needs.

Maximize your productivity, achieve superior bending results, and experience the Durmark difference. Contact us now and let us help you unlock the full potential of your manufacturing operations.

.png)

.png)